|

bth amber mk iii (sl5698)

Genre: Enclosed Horizontal Traverse Low Pressure Sodium Lantern

The low pressure sodium discharge lamp was developed by Philips in 1932. After two successful trial installations

(including the first low pressure sodium installation in the UK along the Purley Way, Croydon) the first commercial installation

was installed by Liverpool Council in 1933 using specially commissioned lanterns from Wardle.

The development of lanterns continued through the 1930s and accelerated when it was determined that the lampís brightness and

its long length made it less susceptible to glare. Lanterns with bare bulbs suspended over an overhead reflector (the so-called "seagull" lanterns)

quickly followed. Glass manufacturers were initially slow as the first plate refractors for low pressure sodium lamps didnít appear

until the end of the decade.

The advantages and disadvantages of low pressure sodium were readily debated, especially when an alternative (the medium and high

pressure mercury discharge lamp) was also available. The monochromatic light was considered especially useful for arterial

and traffic routes, the lampís shape cast a wide beam across the road surface, the light was also considered more penetrating

in foggy conditions and it was the most efficient light source being manufactured. However, the light was also considered

inappropriate for high streets, promenades, civic areas and residential streets and so some lighting engineers

restricted its use to traffic routes only. Therefore low pressure sodium became known as "the driversí lamp."

The arrival of plate glass refractors resulted in large lanterns made of metal frames enclosing heavy glass sheets.

These bulky lanterns continued to be made into the 1950s until being usurped by lanterns with plastic bowls and

machined or moulded plastic refractor plates. The lanterns were still large; the size dictated by the bulky

control gear, but their design and construction was becoming simpler.

The 1950s and 1960s saw huge improvements in the construction and efficacy of low pressure sodium. Early two-piece

designs (dubbed SO) were replaced by the one-piece, more efficient integral design (called the SOI). The development of

linear sodium (SLI) broke the one hundred lumens per watt barrier, lead to a radical rewriting of the British Standards

of street lighting and prompted the development of new families of streamlined lanterns. But it wasnít until the arrival

of a new heat-reflecting technology (called SOX) that a cheap family of extremely efficient bulbs became available.

The energy crisis of the 1970s saw a rethink in street lighting and lamp efficiency became dominant when fuel was both

in short supply and expensive. This saw the large scale removal of colour corrected high pressure mercury, fluorescent and

ancient tungsten lamps by low pressure sodium replacements. The old arguments that the smoky-orange lamps were inappropriate

for residential areas no longer applied. By the end of the 1980s, low pressure sodium was the dominant street lighting lamp used in the UK.

The use of low pressure sodium came under scrutiny again. High pressure sodium, finally developed as a viable technology in the

1960s, was coming of age and offered a compromise of slightly less efficacy with better colour rendering. Questions were

being asked about the physiology of the eye and visual adaptation under low lighting levels; previously the wavelength

of low pressure sodium had been deemed the most suitable, but research now suggested that the eye responded better to white

light. Concerns were raised about light pollution and the low pressure sodium lamp was seen to be the chief culprit

(although it was more to do with older non-cutoff and semi-cutoff optical designs rather than the lamp itself).

By the turn of the century, the age of low pressure sodium was seen as coming to an end. Research in white light technologies,

especially metal halide and a renewed interest in compact fluorescent coupled with the advantages of using white light at

low lighting levels, saw the end of the low pressure sodium lampís dominance. Its use was discouraged in the specifications,

lantern manufacturers started to wind down their production and bulb manufacturers followed suit.

By the end of the first decade of the 2000s, low pressure sodium was in stark decline, and less and less of the UKís

streets were being lit by its characteristic orange glow.

Name: BTH Amber III (SL5698)

Date: Early 1950s - Mid 1960s

Dimensions: Length: 28", Width: 14", Height: 10"

Light Distibution: Non Cut-Off Medium Beam (BSCP 1004 Part One:1952)

Lamp: 140W (later 90W) SOX

History

|

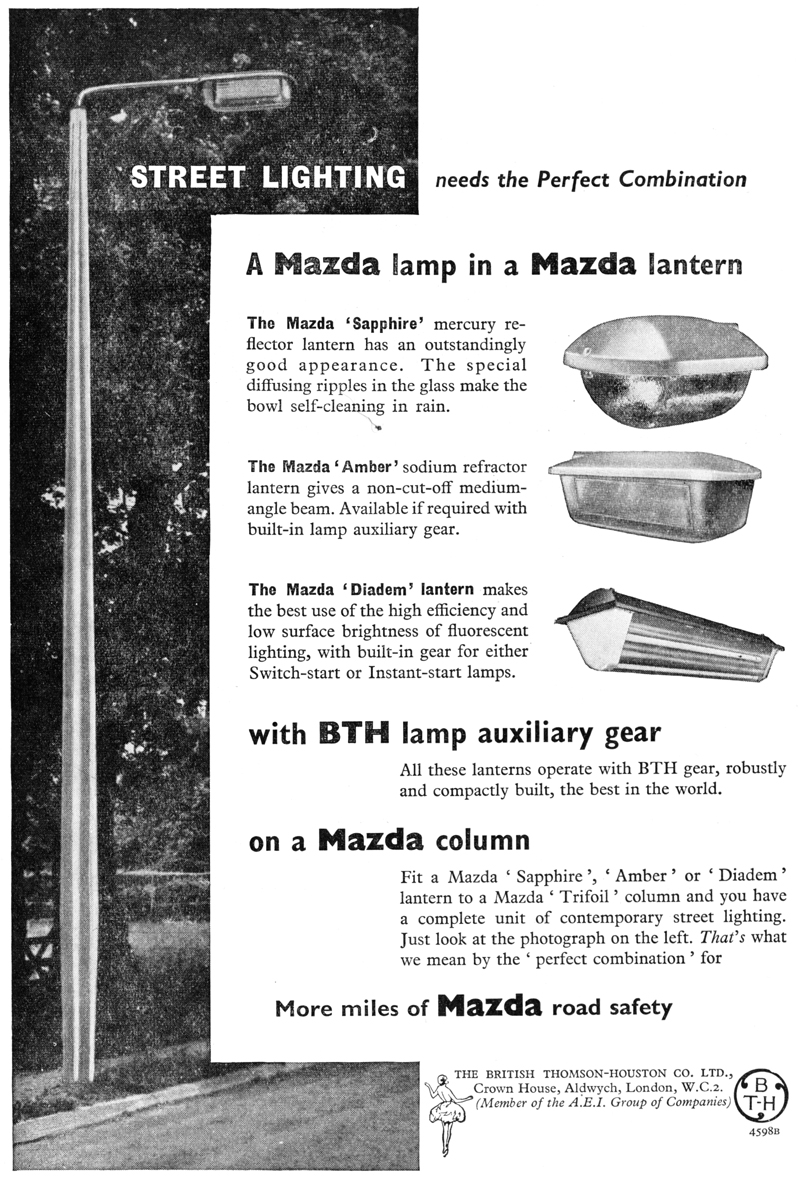

The Amber was the name given to the family of BTH's low-pressure

sodium lanterns. BTH gave their lanternís purely functional names

(a trait which continued to successor companies AEI and Atlas),

so the name continued for over a decade as the lantern evolved. The range followed the classic

design of post-war lantern design: starting with a relatively sleek lantern with an aluminium

canopy and Perspex bowl with refractor plates, evolving into much larger lantern designed to

carry the heavy gear of the time.

The Amber MK III and MK IV became classic designs, installed in

large numbers across the country in the second half of the 1950s. The MK IV

became especially successful, being accepted by the Council of Industrial Design for Design Review,

and successfully retained the lantern's handsome profile and increased its ease of use

(by replacing the large knurled screw which held the bowl with far more user-friendly toggle catches).

The lantern was retained in the range during the "great reorganisation" of BTH

with its sister companies, as AEI consolidated and rebadged its disparate

companies. It was eventually discontinued in the early 1960s, replaced by another lantern called

Amber, which radically altered all aspects of the design, and removed any family

resemblance (this lantern eventually becoming known as the Alpha 9).

|

Popularity

The Amber MK III series was popular throughout the country.

Identification

The lantern was easily identified by curved aluminium canopy and deep curved bowl

with large plate refractors. The MK III also had a large knurled screw

embedded into the road-facing end of the lantern. A large BTH logo

was embossed on the top of the canopy and a sticker (often now perished) identified

the maker and the lantern's catalogue number.

Optical System

The light flux was controlled by two large Perspex refractor plates which were stuck on

either side of the bowl. These produced a medium-angle beam in accordance with BCSP 1004:1952.

A white flat perspex sheet was sometimes fitted into the canopy to act as a secondary reflector

system; this was an option if there was no gear fitted.

The lamp was mounted low in the base of the bowl so optional gear could be fitted.

Gear

According to adverts, the lantern could be supplied with or without gear. This affected

the overall design of the lantern resulting in its characteristic deep bowl and low mounted lamp.

The BTH Amber III (SL5698) In My Collection

|

|

facing profile

The BTH Amber MK III was a popular lantern and was installed in many towns and

cities throughout the UK. Two were installed in Cambridge: one was located on Mill Road near the

council depot, and another was installled along Cherry Hinton Road. All the other lanterns in

Cambridge were BTH Amber MK IVs and AEI

Amber MK IVs. (There is also a theory that there was only ever one of these lanterns in Cambridge and it

was installed in Mill Road; only to be moved to Cherry Hinton Road when the later had many of its columns sleeved

and the Mill Road scheme was replaced. Note also that the Mill Road example stood outside the entrance to the Mill Road Depot).

|

|

|

|

front profile

The bowl was large and deep to accommodate the large leak transformers and condensers of the 1950s.

The base and ends of the bowl were slightly textured to facilitate extra diffusion of the light.

|

|

|

|

trailing profile

Despite many years of service, the lantern was still in good condition. The bowl and refractor plates

were made of Perspex and had slowly become milky due to the action of ultra-violet light. The Perspex

of the bowl was especially thick and this probably explained why the bowl had no damage after

being installed for 50 years.

|

|

|

|

canopy

The canopy was a heavy casting of aluminium alloy. The area over the front edge of the lantern

was extended, forming a lip into which the knurled screw was located.

|

|

|

|

logo

A large BTH logo was centrally positioned in the canopy. At some point, the

lantern was also converted to use a photo-electric cell, and a hole was drilled into the canopy so

the cell cound be fitted.

|

|

|

|

pedestrian view

The bowl was held in place by a curved section of metal rod. This was bolted to the pavement side of

the lantern by two flat steel clamps which formed a hinge. At the road end of the lantern, a notch in

the metal rod engaged with a large stainless steel knurled screw which allowed the bowl to be screwed

into place.

The later Amber MK IV changed this design and two sprung-steel catches were

used instead.

|

|

|

|

vertical

The bottom of the bowl was unadorned allowing the flux from the lamp to illuminate

the area around the base of the column.

|

|

|

|

interior #1

The interior of the lantern featured the necessary drilled holes to support

the lamp assembly, lamp support, earth screw, terminal block, fixing screws, leak transformer,

power-correction capacitor and optional over-head reflector.

A sticker was once stuck to the underside of the canopy, centrally located near the knurled screw.

This had long gone, but the lantern's catalogue number was also stamped into the metal over it

and could still be read: SL 5698/087946.

The original neoprene gasket had mostly perished and was replaced with a new one.

|

|

|

|

interior #2

The lantern was clamped to the bracket by two locking bolts (the later

Amber MK IV used grub screws). To facilitate access to these,

the lampholder was designed with a dog's leg, so that the lamp could be

positioned across the entire length of the lantern.

|

BTH Amber MK III (SL5698): As Aquired

This lantern was originally installed along Cherry Hinton Road, Cambridge. It was one of four

lanterns rescued when the road was relit in 2015 as part of the Cambridgeshire-Northamptonshire PFI.

The columns along Cherry Hinton Road were part of an experimental sleeving scheme in the late 1980s.

The top of the Stewarts And Lloyds gas reservoir columns were removed along with the

REVO brackets, and the lantern was reinstalled on a new steel sleeve.

This sat on top of the bracket extrusion cast into the gas reservoir columns.

This modification was only carried out along Cherry Hinton Road and Babraham Road. I suspect the

council were concerned by corrosion of the bolts holding the brackets to the columns and were

looking into cost-effective solutions for extending the life of the existing installation.

However, the sleeving option was not continued. (Many of the brackets had new bolts fitted in

the 1990s).

The lantern can be seen on the right and it was dayburning for its last months of service.

Four lanterns were rescued from this stretch of Cherry Hinton Road. This included

(clockwise from top left): this BTH Amber MK IV A10600 with

replacement bowl, BTH Amber MKIII (SL3598/087946),

REVO Silvergold and a

BTH Amber MK IV A10600. The Amber MKIII SL3598/087946

was one of two which were installed in the city.

My thanks to Balfour Beatty who gave me permission to remove these lanterns.

The shot shows the interior of the lantern before restoration. The drilled photocell

hole was retained, wiring tidied and replaced, and the gasket was renewed. Apart from that, there was

little else to do other than give the lantern a thorough clean. The remnants of the sticker

can just been seen near the hole for the knurled screw.

|