|

GEC Z8832/70

Genre: Enclosed Horizontal Traverse High Pressure Sodium Lantern

As soon as the low pressure sodium lamp (LPS) was developed, the race was on to develop a version which would run at high pressure (HPS).

The research was stimulated by the prospect of the spectral broadening of the light emitted from such a bulb and

the improved colour rendering which would result. However the development was hampered by the lack of a translucent material which

could withstand the chemical attack of sodium vapour at extremely high temperatures and pressures.

It wasnít until the early 1960s that General Electric (GE) cracked the problems,

closely followed by the GEC and Philips. A prototype high pressure sodium lamp was

exhibited at the APLE's annual conference in 1963, but it wasnít until 1966 that the GEC erected an experimental installation

along East Lane, Wembley (which, incidentally, also saw the first experimental medium-pressure mercury installation over thirty years before).

The first commercial installation in the UK was erected along the Southend ring road, but it was the City Of London who gained the most

recognition by beginning a radial upgrading of all their lighting to high pressure sodium in 1967. As the early HPS bulbs were designed

to be retrofitted into existing mercury installations, the lanterns chosen by the City Of London were slightly modified versions of

existing mercury lanterns.

The first true HPS lanterns (designed from scratch with the new light source in mind) appeared in the late 1960s and early 1970s. All

these lanterns utilised a cross-over design: whilst this was an adaption of existing mercury lanterns, it also moved the lamp up into

the lanternís canopy (where it could not be directly viewed by drivers, thus minimalising the glare) and allowed designs to cater for

both cut-off and semi-cut-off.

Wider adoption of high pressure sodium was stalled by the energy crisis, as it couldnít match the efficiency of its low pressure sodium brother.

Councils, believing in the simple maximum lumens per watt paradigm, replaced existing tungsten, mercury and fluorescent schemes by

low pressure sodium. So it wasnít until the 1990s that HPS started appearing in greater quantities.

With its efficiency between high pressure mercury and low pressure sodium, HPS became even more attractive when LPS was finally exorcised

from the British Standards of street lighting (as it didn't provide an adequate colour rendering). However, it didn't remain as first choice for

new and replacement lighting schemes for long. Renewed interest in fluorescent (from compact fluorescent sources), the emergence of affordable

metal halide and the possible introduction of LED have all questioned the automatic selection of high pressure sodium for schemes.

Therefore by the end of the first decade of the new century, high pressure sodiumís position as the natural choice for street lighting

was coming under pressure.

Name: GEC Z8832/70

Date: Mid 1970s -

Dimensions: Length: 54cm, Width: 27cm, Depth: 18cm

Light Distibution: Cut-Off (BS 4533 Part 2)

Lamp: 35W SOX, 80-125W MBF/U, 50-70W SON

History

|

|

The GEC Z5530 range of lanterns were the first side-road lanterns produced by the GEC

specifically designed for the newly introduced High Pressure Sodium (HPS) lamp. Various existing lanterns originally designed for

high pressure mercury lamps had been adapted for HPS, but the Z5530 range was the first to take full advantage of the new bulb.

It shared many design traits with its competitors (such as the Thorn Beta 79) but its design

could be seen as a logical development of the earlier Z8691 lantern. The bulb and gear were housed in two separate

compartments, the optics were based on a cross-over reflection system, and the canopy was made from moulded GRP.

It could also take high pressure mercury (MBF/U) and, originally, low pressure sodium (SOX) therefore allowing the lantern to be

installed within an existing scheme.

It was also one of the last lanterns designed by the GEC.

By the end of the 1980s, the street lighting section was moved to the companyís OSRAM division before being sold to

Siemens and subsequently purchased by Whitecroft (now Indal WRTL).

Each company manufactured the lantern with little change: so examples included the GEC Z5530 family, the

OSRAM Z5530 family, the Siemens Z5530 family and finally the WRTL SRL8.

The lantern is still being made today as the Indal WRTL SRL8F.

|

Popularity

It is a popular lantern and can be found installed throughout the country.

Identification

Identification can be tricky as the lantern shares many similarities with its competitors (such as the Thorn Beta 79

and DAVIS GR70). However, the lantern features a distinctive square extrusion above the lower rim of

the canopy where the bowl hinge engages with the side of the canopy.

Optical System

Two curved polished textured metal reflectors comprise the primary optical system which produce a cross-over

flux distribution (which, in turn, gives better control of the degree of cut-off of the light produced).

The secondary optical system comprises a white plastic over-reflector mounted above the bulb which reflects light emitted above the bulb back

towards the street surface.

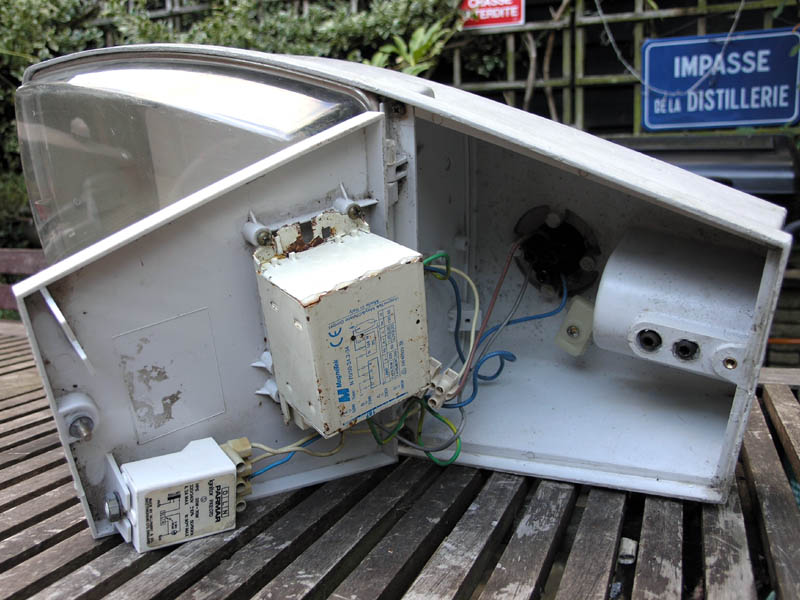

Gear

The gear is housed in its own gear compartment. This has a lower IP rating than the lamp compartment and access is

achieved by unscrewing a single screw.

When opened, the cover plate swings open and all the gear is mounted on its opposite site. Three components are usually

screwed to the cover plate: the main lamp choke, a power correction capacitor and an ignitor.

The GEC Z8832/70 In My Collection

|

|

facing profile

I can't recall the provenance of this lantern. However, it was installed somewhere as the lantern

has been modified and repaired whilst in service.

|

|

|

|

front profile

The bowl is held in position by a single stainless steel clip.

|

|

|

|

trailing profile

The lantern was painted white whilst in service. Normally this wouldnít be necessary as the canopy

is made from Glass Reinforced Plastic (GRP). Some possible reasons for the paint include: an attempt to waterproof the lantern

after the GRP became porous (a known problem with some later GEC GRP low pressure sodium lanterns); protection

against flaking glass fibres (a known problem with several lantern types); or slightly over-zealous restoration by a collector.

|

|

|

|

canopy

The GEC usually embossed their logo on the canopy of their lanterns but it's surprisingly absent from the Z5530 range.

|

|

|

|

logo

Additional marks and scuffs suggest the lantern was painted whilst in service and it wasnít a post-removal restoration.

(Incidentally note the black insulation tape over the photocell; this allowed me to turn on the lantern in the daytime).

|

|

|

|

pedestrian view

This classic view clearly shows the two reflectors positioned either side of the bowl. The gear compartment plate also

carries a servicing warning message which became standard for many of the GECís lanterns produced in the 1980s.

|

|

|

|

vertical

The bowl is simply clear and doesn't carry any additional refractors.

|

|

|

|

interior #1

The secondary optical system comprises a simple white plastic sheet screwed into the canopy of the lantern. Such an addition is questionable,

particularly in a white plastic lantern, but perhaps the range was available in different colours, so a white over reflector

was added as standard.

The lantern bares the number "ZD 6048" on the canopy under this cover. This was a GEC classification code and is

the only reason I believe this was a GEC lantern (and not the later Siemens or Whitecroft models).

|

|

|

|

interior #2

The gear compartment is now a mess and suggests the lantern has been repaired several times in service. The original

choke and power correction capacitor have gone. Their replacement is an Italian MagneTek choke for 70W SON. The Paramar

ignitor is probably the only original component still in-situ.

The installation of the new gear has not been done well and the terminal strip connector is now loose in the gear

compartment (it should be screwed to the lug near the photocell). It will be tidied up in the future.

The lantern's identification sticker is also missing. This was originally stuck in the square shaped area on the gear compartment tray next to the ignitor.

|

GEC Z8832/70: Night Burning

GEC Z8832/70: As Aquired

This was one of the last lanterns designed by the GEC; of cut-off,

reflector design, it catered for the introduction of the SON-E lamp, but could also take

mercury or low-pressure sodium.

|