|

The cut-off Amberline is an enclosed lantern for one 200 watt Mazda Sodium Linear discharge lamp.

Application

The cut-off Amberline may be mounted at heights between 25 and 35 ft. at 80 to 140 ft. spacing according to the intensity

required on the road surface. The Amberline is accepted by the Ministry Of Transport for Class 'A' road lighting.

Specification

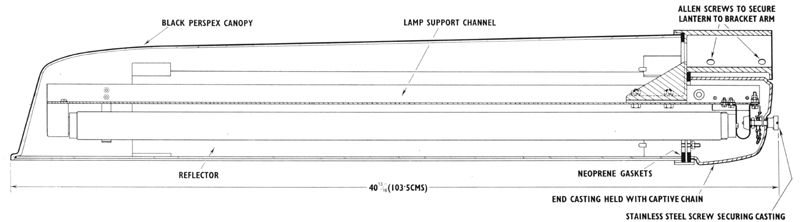

The lantern consists of an end casting and a 'Perspex' enclosure which houses specular magnesium aluminium alloy reflectors for

accurate light control.

The end casting, aluminium alloy (LM6), has a removable cover to give easy access for re-lamping and normal maintenance. The cover is

secured in place by a stainless steel coin slot screw and a safety chain is fitted to allow the cover to hang freely when it is removed

for maintenance.

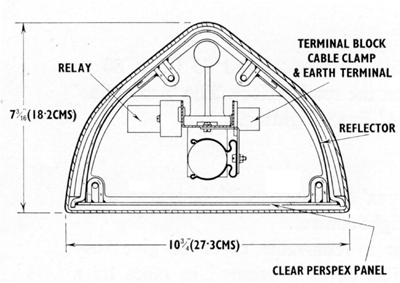

The casting carries the lamp support channle assembly which includes a terminal block, cable clamp, earth screw and thermal relay. At the roadway

end of the support channel a retractable bi-pin lamp holder (72/01013) is fitted and a metal stirrup is provided to act as a guide during

re-lamping operations. At the lantern access end a push on bi-pin holder (72/01018) is fitted on short flexible leads to allow slight

freedom of movement.

The 'Perspex' enclosure comprises a black 'Perspex' canopy cemented to a flat clear 'Perspex' panel. The specular magnesium aluminium alloy

reflectors are fitted within the canopy and the entire 'Perspex' assembly is securely held in position by four 'J' bolts passing through

'Perspex' blocks which are firmly bonded to the walls of the enclosure.

The top of the casting includes the side entry facility and the outteach bracket is secured by 'Allen' screws located under the canopy for

protection and appearance.

Light Distribution

Specular aluminium alloy reflectors housed in an opaque 'Perspex' canopy give a cut-off distribution as defined in British Standard

1788 (revised).

Maintenance

Normally, only for lamp replacement at 4000 hours. This is a simple operation as the lamp is withdrawn through the rear after opening

the end plate.

Product Number 51/71200

Weight 17 lb. (7.7 kg)

Weatherproofing

All 'Perspex' to metal, and metal to metal, joints are rendered weatherproof by the use of Neoprene gaskets which are used for

sealing the 'Perspex' envelope to the end casting and also between the access cover and the main body casting. Breathing

can only take place through the wiring entry and the lantern should therefore remain clean in service without attention for

exceptionally long periods.

Allen screws secure the lantern to the bracket and, enclosed by the lantern, are protected from atmospheric corrosion.

Mounting

Side entry for 1¼" plan B.S.P. 4" long.

Control Gear

One 61/22116 leak transformer, tapped 200/250V, and one 62/63206 capacitor for power factor correction to 0.85 or better, are

required in the base of the column. Dimensions of the transformer are 8½" long, 4½" wide, 4½" deep. One 61/72401

thermal relay is fitted in the lantern. Total circuit watts 235 approx.

The Company reseve the right to change without notice the design or the specificaiton of equipment included in this

publication.

|