|

broads

|

Broad And Company Limited

2, 3, & 4 South Wharves,

Paddington,

London W2

England

|

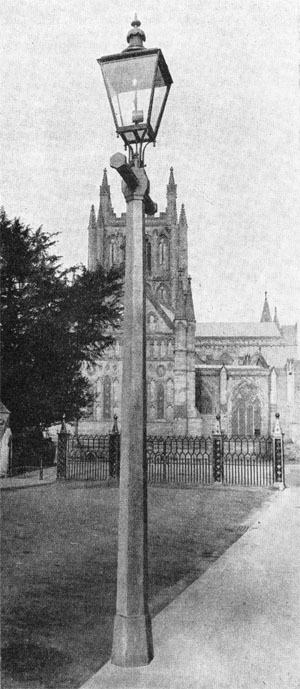

Manufacturers of the Broadcrete Lighting Column.

A collaboration of Broad & Co., Ltd., London and John Ellis & Sons., Ltd., Leicester has

resulted in fundamental improvements in the design and construction of Concrete Lighting Columns. The tendency to

reproduce in concrete the designs associated with older materials has been carefully avoided. Broadcrete Lighting Columns

are devoid of superfluous ornamentation. Their clean, simple lines have a practical as well as aesthetic value,

adding to their weathering qualities and appearance, and permitting of uniform treatmetn during manufacture. The continuous

surface ensures overall cleaning by rain, which is free to flow to the pavement underhindered by projections or pockets.

The Columns are ground and semi-polished all over. They are manufactured by the high frequency vibration method and

comply with British Standard Specification 1308 1946. Special roots can be provided to suit difficult conditions of sites.

The heaxgonal section is particularly adventageous on narrow footways since it provides the minimum obstruction

when located with two opposite faces parallel to the kerb. One of the many important features is Broad's patent

solid reinforced concrete locking door which is a standard fitting to Columns where equipment chambers are required in

the base. They are waterproof and tamperproof and match the Column exactly. Reinforced concrete brackets, available in

various designs and in the same high-grade finish, are secured by means of Broad's patent safety non-rotating

fixing device. One-piece reinforced concrete ladder arms, where required, are similarly fixed. The columns are in large

scale production. - APLE Conference Programme 1946

Broad & Company's display at Princes Park, Southport, during the APLE Conference. - Public Lighting #47, 1947

Design: Broadcrete Columns are designed to give full aesthetic expression of the material of which they

are made. Clean, simple lines, unbroken by spurious ornamentation, are the outstanding characteristic of all designs,

which possess a quiet dignity and beauty harmonising equally with ancient buildings or with a modern architectural

setting.

Finish: Columns and Brackets are ground on all faces to ensure perfect lines and arrises; they are then prepared

in either: (a) Fine Grey Floated Finish giving a uniform light-grey appearance and even surface; (b) Smooth Ground Semi-polished

Finish in which the natural colour of the Mountsorrel granite aggregate is exposed.

Materials And Structure: Columns and Brackets are of the finest quality reinforced granite concrete construction,

hexagonal in section, manufacturered by the high-frequency vibration method. The aggregate consists entirely of

selected Mountsorrel granite, crushed and graded.

Reinforcement: All columns are reinforced throughout their length to withstand British Standard loadings.

Equipment Chambers and Doors: Chambers are provided in two standard sizes, namely 18in. and 27in. These are fitted with

Broads' patent solid reinforced concrete doors, hung on heavy brass hinges by patent fixing devices; machined brass lock and

safety stay are incorporated. The weather grooves and sloping cill will prevent any possibility of driving rain penetrating to the

chamber.

Brackets: Reinforced concrete brackets are available in a variety of designs and finished to match the columns. They are tubed for

wiring and terminate in a threaded nipple. Brackets, ladder arms and terminals are mounted on columns by means of a solid-drawn tubular

steel dowel of hexagonal cross section, removable and accurately located in a solid-drawn steel hexagonal socket, whcih is welded to the

reinforcement and cast into the columns.

Ladder Arms: These are supplied in two sizes i.e. 2ft. and 3ft. overall. They are reinforced monolith units with central

hexagonal socket fixing, ensuring non-rotation.

Terminals: These units are supplied as a finish to the column where concrete ladder-arms are not required.

Spigots: Removable galvanized cast-iron fluted spigots, 3in. dia. x 3in. high, with grub screw, are supplied for metal brackets or

directly-fitting lanterns.

Expanding Bases: All columns are mounlded with expnding hollow bases, combining lightness with greater stability when erected.- APLE Conference Programme 1947

References:

APLE Conference Programme London 1946

APLE Conference Programme Southport 1947

- External Links:

- Grace's Guide

|