|

Specification Clearmain 9454/5 and 9464/5

Use

Main road lighting, mouting height 25 ft. (7.62 m), spaced up to 120-150 ft. (36.55-45.6 m),

road widths up to 40 ft. (12.19 m).

Lamp

140W Osram integral jacket or detachable jacket sodium lamp, type SO/H.

Mounting

The Z9454 or Z9464 side entry lantern requires not less than 5 in. (127 mm) of horizontal

unthreaded 1.1/4 in. B.S.P. When fully home two 7/16 in. Allen-type grub screws grip

the barrel. Water running along the bracket arm is prevented from entering the lantern

by a water baffle.

The Z9455 and Z9465 top entry lanterns are tapped 1.1/4 in. B.S.P. and are supplied with

a locknut.

Lantern Body

One-piece light alloy die-casting. The inner surface of the body is enamelled to act as an

over-reflector. The body carries the lamp steady and lampholder wired with heat-resisting

insulating wire to a porcelain terminal block. An earthing screw and porcelain cable cleat

are provided.

In the Z9464 and Z9465 lantern, the body is arranged to house a transformer and a power

factor correction capacitor, these items being supplied screwed onto bosses in the

body casting. Covering the gear is an over-reflector finished in glossy synthetic white

enamel. Provision is made for the fitting of fuses if required. The lampholder is wired

with heat resisting insulted wire to the terminal block on the lampholder.

Lampholder

Porcelain B.C. The lampholder position is fixed.

Optical System

Light control is provided by two 'Diakon' refractor plates. The prismatic sides of

the plates are bonded one to each inner side of an injection moulded 'Diakon' bowl. Both

inner and outer surfaces of the bowl are smooth for easy cleaning. The ends of the bowl have

a rimpled finish. The bowl is fitted with a light alloy rim hinged to the lantern body

and fastened by means of a robust stainless steel spring catch. The bowl can be lifted

off the hinges if required to facilitate cleaning. A tropicalised felt gasket ebtween the

body casting and bowl ensures a weatherproof seal when the lantern is closed.

Weathering Finish

The alloy used is specially selected for its resistance to corrosion. Further protection

is obtained by the use of a special one-coat aluminium-finish stove enamel.

|

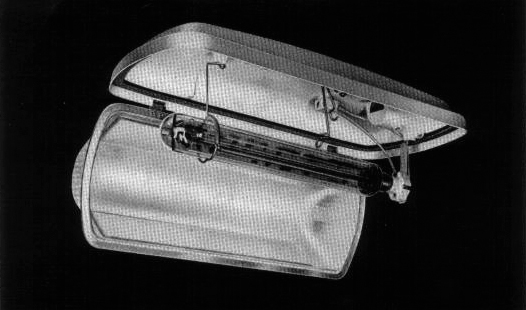

| The Z9454 side entry lantern with the bowl opened to show the lamp mounting and general construction. |

|

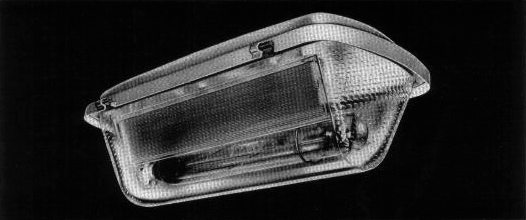

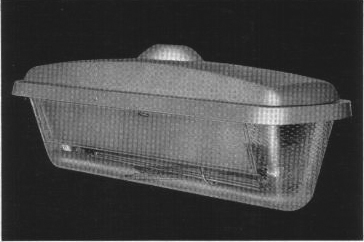

| View showing the general shape of the top entry Z9455 lantern. |

|

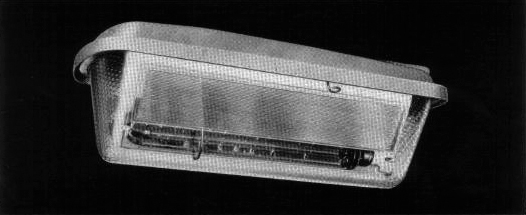

| View showing the general shape of the side entry Z9464 lantern. |

|

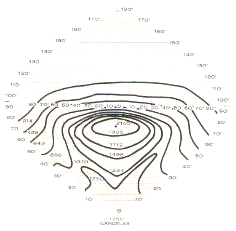

The iso-candela diagram is based on an average lamp light output through life from a

140W Osram integral sodium lamp (9,800 lumens average, applicable at time of print).

Directional intensity ratio: 1.8:1

Light above horizontal: 11%

Light output ratio: 86%

Lumens in the lower hemisphere: 7383

Light distribution data are given for the guidance of the lighting engineer and represent the

average results of laboratory tests on a number of lanterns taken at random from stock.

The data are based on the lamp characteristics stated; if the latest lamp efficiency is different,

the candela or lumen values should be calculated in direct proportion to the relative lamp

lumens.

|

|

| View showing the general shape of the Z9455 top entry lantern. |

|

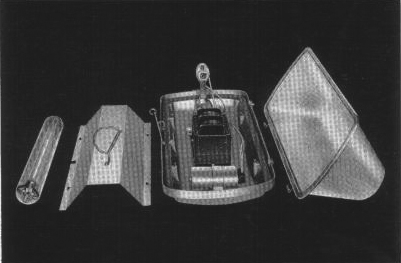

| The Z9464 side entry lantern with its refractor bowl opened and lifted

from its hinges. The lamp and over-reflector have been removed to show the lamp operating

gear and the side mounting entry. |

Lantern Weights

Z9454: 11½ lb (5.22 kg)

Z9455: 10 lb (4.54 kg)

Z9464 complete with gear: 29 lb (13.1 kg)

z9465 complete with gear: 27 lb (12.2 kg)

|

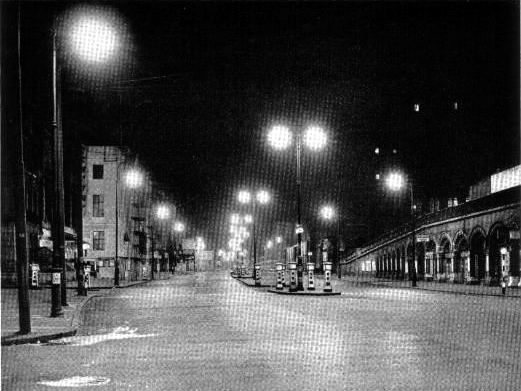

| The photograph shows part of the installation in Euston Road, St. Pancras, of G.E.C.

lanterns using Osram 140W integral sodium lamps. This is the first complete installation using

this lamp in the world. |

|