|

Specification Clearmain 8401

Use

Main road lighting, especially roads in the vicinity of airfields. The lantern has a medium

angle beam distribution. Peak intensity occurs at 75 degrees, and at 80 degrees it is

two-thirds of the maximum value. The cut-off type of construction produces a rapid run back

over 80 degrees falling to a negligible figure at the horizontal. The lantern falls within the

specification issued by the Ministry Of Transport, whcih is reproduced on the back page.

Lanterns should be mounted at a height of 25 ft. and spaced not more than 120-130 ft.

apart. Suitable for road widths up to 50 ft.

Lamp

For use with a 250W or 400W Osram MA/V lamp.

Mounting

Top entry, standard tapping 1.1/4 in. B.S.P. The lantern can be provided with a device

to give levelling in any plane to a maximum of 5 degrees from the horizontal when

required with the M.O.T. specification overleaf.

Lantern Body

Totally enclosed die-cat aluminium-silicon alloy. The body carries the terminal block,

wiring, magnetic deflector, lampholder, lamp steady and the reflectors which make up the

optikon.

Lampholder

Porcelain G.E.S. wired with heat-resisting insulated wire to a porcelain terminal block.

Over-Reflector

Immediately above the lamp is a non-magnetic reflector. The reflector plate serves the

dual purpose of reflecting light and preventing rising hot air from overheating the magnetic

deflector.

Magnetic Deflector

The magnetic deflector enables an MA/V lamp burning horizontally to operate as efficiently

as it does in its normal perpendicular position. The deflector is mounted on the reflector

plate. It is connected in series with the lamp and consumes 1 watt. The magnetic deflector

can be used with either the 250W or 400W lamp, conversion from one wattage to the other

being made by changing a connection.

Optical System

Two curved glass mirrors are held inside the body to provide the light control.

All mirrors are first quality and are coppered, lead backed and secured by clips. A

die-cast light alloy frame, hinged to the body and secured by a stainless steel toggle

catch, supports a pressed heat-resisting glass dish.

Weathering Finish

The alloy used is especially selected for its resistance to corrosion and is processed to give

a pleasing appearance.

|

| The lantern opened to show optical system, lamp mounting and over-reflector

carrying the magnetic deflector |

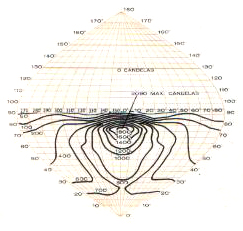

The iso-candela diagrams are based on an average lamp light output through life from

a 250W Osram MA/V lamp (8,750 lumens average).

| 250W | 400W |

| Directional intensity ratio | 3.1 | 2.6 |

| Light above horizontal | 2% | 2% |

| Light output ratio | 56% | 55% apprx |

| Lumens in the lower hemisphere | 3810 | 7080 |

Light distribution data are given for the guidance of the lighting engineer and represent the

average results of laboratory tests on a number of lanterns taken at random from stock.

The data are based on the lamp characteristics stated; if the latest lamp efficiency is different,

the candela or lumen values should be calculated in direct proportion to the relative lamp

lumens.

Lantern weight: 28lb (12.7 kg).

|