|

Stanton: Staff Handbook

In addition to publishing The Stanton News, an in-house magazine for employees, Stanton

also gave each new recruit a hardback book called "The Iron Dale" detailing the company, history and its products. The

covering letter, and the section mentioning street lighting is given below:

...lining applied by centrifugal force, which expels the water and forms the lining in a few minutes.

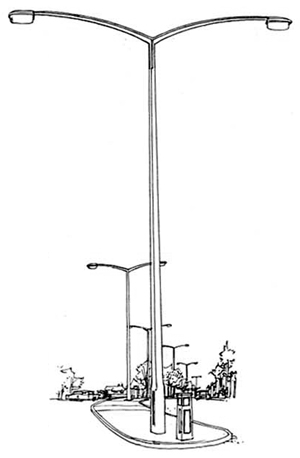

In this new field of concrete, research has been ceaseless. One of its early results was

the decision, in 1937, to apply the spinning process ot the making of lighting columns. A new plant was

built and Stanton became the first people in the world to produce spun concrete lighting

columns. Street lighting in many parts of the world today is the better for that 1937 decision.

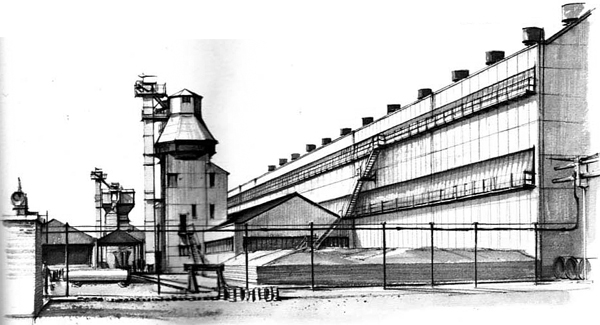

The spinning shop, storage hoppers and elevators of the prestressed concrete pressure pipe plant

The concrete plant, like the rest of Stanton, 'went to war' in 1939. It built thousands

of pre-cast concrete air-raid shelters, and many other things. But one product in particular, occasioned by

war, staryed on to play an important part in world transport in time of peace. During the war the lack of

timber for railway sleeers became serious. Stanton examined the possibility of making

concrete sleepers. They were a great success and well over a million were made. It is not an exaggeration

to say that but for those concrete sleepers many of hte specially built war munitions factories could not

have operated. The war over, the concrete sleeper stayed. Though they are more costly than timber sleepers,

their life is five tiems as long and they are still today among the products of Stanton.

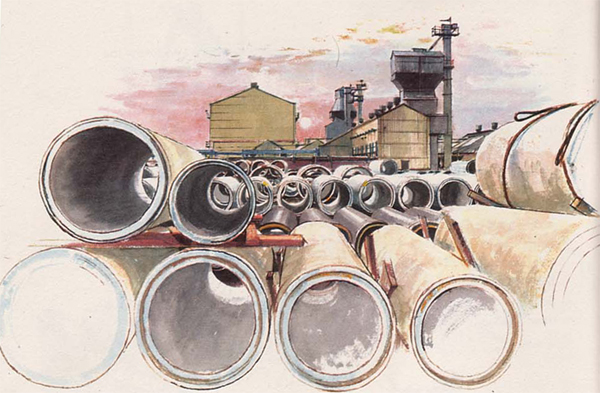

Prestressed concrete pressure pipes in one of the works stockgrounds

From concrete to spun concrete to prestressed spun concrete; that has been the steady pattern of progress.

And always these progressive steps have been backed by searching experiment. Tests and experiments were carried

out for a long time on the use of prestressed concrete before the company began making spun concrete lighting

columns by prestressed methods. One more 'first in the world' was chalked up to Stanton. These

lighting columns, capable of carrying the same load as a normal reinforced column, contain only about

half the quantity of steel.

It soon became apparent that, in addition to the normal centrifugally spun concrete pipe, there

was a need by industry generally for an alternative type of pipe - particularly in the larger

diameters - for the conveyance of water at high pressure. Prestressed concrete pipes were the

answer. A completley new self-contained plant, the only one of its kind in the United Kingdom,

was put down specifically for their manufacture. One again Stanton had met with

outstanding success [meeting] another of industry's needs. These pressure pipes made an immediate

appeal to British engineers and they have been installed by many of the country's Water Boards.

Although they were developed initially for high pressure water supply, they have proved suitable

for other purposes, including the conveying of gas.

It soon became apparent that, in addition to the normal centrifugally spun concrete pipe, there

was a need by industry generally for an alternative type of pipe - particularly in the larger

diameters - for the conveyance of water at high pressure. Prestressed concrete pipes were the

answer. A completley new self-contained plant, the only one of its kind in the United Kingdom,

was put down specifically for their manufacture. One again Stanton had met with

outstanding success [meeting] another of industry's needs. These pressure pipes made an immediate

appeal to British engineers and they have been installed by many of the country's Water Boards.

Although they were developed initially for high pressure water supply, they have proved suitable

for other purposes, including the conveying of gas.

Behind all this production, whether it is iron or concrete, are two groups who might perhaps

forgive the label of 'backroom boys'. In the general sense there is no end-product to their

highly skilled work; but end-products would not be possible without them. Firstly there is the

Engineering Department - the team of designers, draughtsmen, civil, mechanical, electrical and

fuel engineers and all manner of technicians who have an all-the-year-around double-barrelled

job on their hands. They are the men who keep the whole of the plant at

Stanton working; they are also the men responsible for the installation of new

plant, one of their biggest jobs being the design and installation of the Ore Preparation Plant

which started in 1956 and was completed in 1959. Their Wagon repair shops and road vehicle servicing

workshops keep this endless chain moving. Considerable additional tonnage is handled by outside

road service vehicles for which Stanton has hring arrangements. The department,

through its Liverpool office, also controls and arranges shipping through...

Behind all this production, whether it is iron or concrete, are two groups who might perhaps

forgive the label of 'backroom boys'. In the general sense there is no end-product to their

highly skilled work; but end-products would not be possible without them. Firstly there is the

Engineering Department - the team of designers, draughtsmen, civil, mechanical, electrical and

fuel engineers and all manner of technicians who have an all-the-year-around double-barrelled

job on their hands. They are the men who keep the whole of the plant at

Stanton working; they are also the men responsible for the installation of new

plant, one of their biggest jobs being the design and installation of the Ore Preparation Plant

which started in 1956 and was completed in 1959. Their Wagon repair shops and road vehicle servicing

workshops keep this endless chain moving. Considerable additional tonnage is handled by outside

road service vehicles for which Stanton has hring arrangements. The department,

through its Liverpool office, also controls and arranges shipping through...

Many thanks to Duncan Maguire for the scans.

A typical street at Kirk Hallam where, on the company's estate, houses have been built for those who work at nearby Stanton

|