|

During recent years, Kuwait, the small State at the head of the Persian Gulf, has achieved a new prosperity and unexpected prominence.

Consequent on the signature of an agreement with the Kuwait Oil Company, which brought vast reserves to the State, a decision was made

to replan completely the old walled town and expand it into the surrounding desert.

The task of town planning, given to the British firm of architects, Messrs. Minoprio, Spenceley and P W Macfarlane involves

rebuilding a good deal of the old city. Completely modernised roads of 12, 15, 20, 30 and 50 meters in width and a new Civic Centre, are the basis

of this scheme.

Among many other considerations, the question of suitable street lighting for the new town had to be solved. The architects prepared several

designs and models of street lighting units, and from these Mr. J D Addison, M.I.Mech.E., M.I.M.E., the Chief Electrical

and Mechanical Engineer, Government of Kuwait, evolved designs of acceptable standards and lanterns.

Tenders for equipment were invited from both British and foreign electrical firms, and Mr. Addison carefully explained

to all concerned the necessity for a complete "break-away" from conventional design and the need for engineering skill to produce units in keeping

with the location.

First class illumination by means of fluorescent tubes of a "cool" colour were particularly required for night time conditions, and the

colour of the equipment itself was to be sufficiently brilliant to match the sunlight by day. The high temperature prevailing in Kuwait

also demanded equipment able to withstand tropical conditions as well as sand storms.

From the tenders submitted, H E Shaikh Jabir Al Ali As Subah, President of the Department of Electricity, Government of

Kuwait - after approval from the Development Board - awarded the contract for nearly £100,000 of Class "A" Fluorescent lighting units to

Messrs. Siemens Electric Lamp and Supplies Limited of Great Britain. Involving all main roads and an additional 500 units for

Class "B" side roads, Siemens equipment will be used throughout the replanning of the town except for special fittings to be

supplied by another successful British company.

A special manufacturing design team was formed by Siemens to implement the contract. Headed by Dr. J N Aldington,

a team of specialist lighting engineers employed the resources of the Siemens Group to develop the designs of

Mr J D Addison, and a lighting layout for the proposed new town of Kuwait involving 2000 lighting points was the outcome.

Consisting of drawings and coloured visuals, the scheme was based upon British Standards Institution Code of Practice suitably adapted from

local conditions.

Optical control systems for the various types of lantern were designed at the Preston Laboratories of Siemens, and from polar-curves

derived at the laboratory an estimate of the equipment needed for the scheme was made by installation engineers in London.

At the Halifax Works, prototype lanterns were fabricated to determine tooling requirements; inside a sepcial tropical research room, the

lanterns were subjected to conditions of heat and humidity indentical to the Kuwait climate. In addition, lamps, control gear, paints and varnishes

were subjected to prolonged tropical tests which in a number of instances, necessitated special designs for certain components.

One development of these tests resulted in an entirely new starter-switch for the fluorescent lamps, whilst the actual paint finishes

experimented with resulted in a new heat, light, and corrosion proof finish which Siemens have named "Haliglass."

A range of model lanterns and columns was made by Siemens model makers which together with coloured designs, were flown out

to Kuwait by a special plane service arranged by BOAC.

At Siemens Woolwich Works, the question of special high temperature and corrosion resisting cable was reviewed, and a plastic

convered cable for use with the lighting units was produced.

Anti-condensation devices for associated joint boxes were developed at Siemens Spennymoor Works.

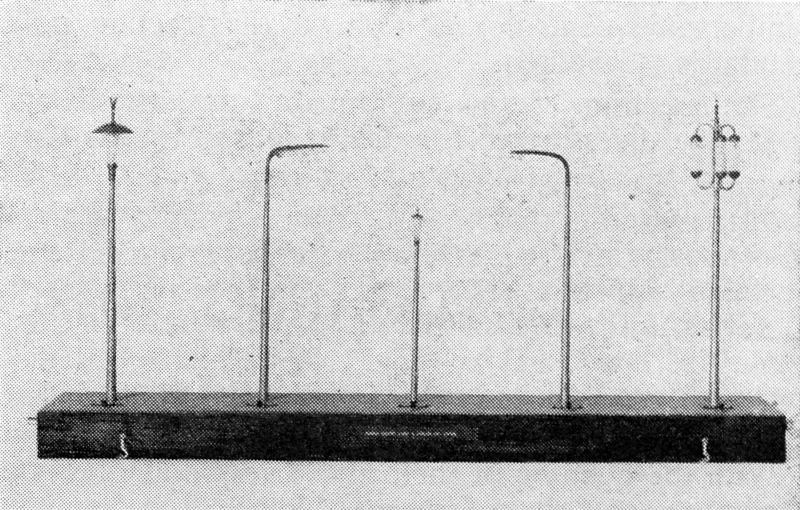

The illustration shows the original Siemens models, and the production of the lighting units for the contract are

well in hand.

The lanterns for the 40 and 50 metre roads will accommodate three 5 foot 80 watt "Sieray" Daylight Fluorescent tubes, and for the narrower

30 metre roadways, two lamp lanterns will be utilised. Special attention is being given to the tapering nature of the

columns and the 5 foot tube lanterns will be tilted at an angle to preserve the smooth flow of the line from the standard into the lantern

itself.

In order to ensure strength, the Siemens lanterns incorporate a cantilever bracket which has proved in practice to be

extremely efficient in withstanding gales and high winds and a tropical "gasket" sealing device prevents the ingress of dust or sand.

The optical control of the high efficiency fluorescent lamps is by means of aluminium reflectors in conjunction with a plastic bowl, and the

lamp control gear is housed within the lantern body. Access to the interior of the lantern is provided by means of a single heavy duty captive

bolt.

Subject to the permission of the Government of Kuwait, Siemens hope to exhibit the Kuwait Street Lighting designs at the forthcoming

Baghdad Trade Fair where the Chief Lighting Engineer of the COmpany will be in attendance to advise on enquiries regarding street lighting

problems.

In addition to the Kuwait project, Siemens are also engaged in lighting schemes in many other countries including Spain,

Argentina, Yugoslavia, Cyprus, Australia and South Africa.

© Institution of Lighting Engineers

|