|

GEC Z8691

Genre: Enclosed Horizontal Transverse Mercury Lantern

The mercury vapour discharge lamp was developed by the GEC in the early 1930s. The first production

quality lamps, rated at 400W, were trialled along East Lane, Wembley in June 1932; and the first installation was erected

early the next year. The lamp was designed to replace the 1000W GLS lamp which was considered a necessity for good quality street

lighting but was unaffordable for most local authorities. The 400W medium-pressure mercury lamp (later called the MA) was

therefore marketed as the cost-effective solution for main road lighting.

It was quickly joined by 250W and 150W rated lamps, both tubular, and both designed for road or industrial lighting.

The colour was often seen as a problem, and the lamp soon earned the nickname “the cadaver” lamp, so various

attempts were made to change its spectral output. Doping the mercury discharge with other metals, running tungsten filaments

in series and covering the outer bulb with fluorescent powders were used to modify the lamp’s colour, but all reduced

the efficacy.

The lamp’s efficiency and colour output could be improved by increasing the pressure in its enclosed arc-tube. This was

initially a problem as the hard-borate based arc tubes couldn’t withstand the increased temperatures and pressures; whilst

manufacturing issues with quartz glass tubes prevented their adoption. It wasn’t until 1936 when Philips solved

the problems with quartz that a new generation of high-pressure mercury lamps were introduced. Manufacturing costs prevented

the quartz based lamps from being made in larger wattages so only lower wattage lamps initially used the quartz technology

(and were therefore called MB lamps).

The smaller MB lamps were offered in elliptical glass bulbs and resembled the shape of tungsten filament lamps. To prevent

engineers installing MB lamps in unprotected circuits – as they required gear to stabilizethe current – the bayonet connector

was fitted with three pins instead of two.

After the Second World War, the mercury lamp was used extensively throughout the UK as part of post-war rebuilding.

New installations were often either low-pressure sodium or mercury. The status quo with the MA and MB lamps remained intact

until the costs of quartz eventually dropped and higher wattages became financially viable; and so the MA lamp was eventually withdrawn.

Whilst improvements were made with the efficacy and ight quality of the lamps throughout the 1950s and 1960s, the lamp remained

less efficient than its sodium counterparts. The introduction of the high-pressure sodium lamp in the early 1960s, which was more

efficient, meant that mercury was rapidly becoming a poor option for street lighting. When the energy crisis of the 1970s hit,

forcing councils to opt for the cheapest running options, mercury joined fluorescent and tungsten as one of the lamp types to

replace.

Despite its disadvantages, mercury still remained popular for residential lighting throughout the 1980s and 1990s, where its

bluish-white light was preferred by some authorities. But the high mercury content of the lamps, and their poor efficiency, meant

that it became increasingly difficult to support in more environmentally sensitive times. The mercury lamp was eventually

removed from the specifications, and its production was stopped in the early 2000s, which resulted in its accelerated demise.

By the 2010s, with massive replacement schemes and the adoption of LED, the era of mercury discharge lighting had come to an end.

Name: GEC Z8691

Date: Late 1960s - Mid 1970s

Dimensions: Length: 580mm, Width: 267mm, Depth: 203mm

Light Distibution: Semi-Cut-Off

Lamp:80-125W MBF/U

History

|

|

The GEC had previously used a traditional pendant top-entry styled lantern for tungsten and mercury vapour

lamps. Such designs were fitted to swan-neck style brackets, but the austere and modern movements which followed in the

wake of the Second World War, plus the introduction of new materials and manufacturing techniques, meant that a fresh

look was taken for this lantern type.

The trend tended towards side-entry lanterns. The GEC responded by modifying their existing range of pendant

lanterns with side-entry options; but the overall combination of this type of modified pendant lantern, with sleek side-entry bracket and non-decorated

column looked ungainly. Therefore the firm designed a new lantern for tungsten and mercury vapour lamps which was smaller, sleeker

and designed for side-entry.

The Z8490 range was the first developed for the market in the 1950s. Its design parameters were brief: side-entry

lantern with die-cast aluminium canopy; newly designed glass refractor bowl and ring; horizontally mounted lamp; and the

absolute minimum of ancillary components. There was no provision for gear, so the lantern's dimensions were kept to a minimum.

The design suffered from an extruded spigot which was mounted over the top of the lantern. This gave the lanterns an unfortunate

drooping appearance when mounted on the bracket. Therefore the Z8495 improved its aesthetic appeal by moving the spigot into

the canopy and angling the lantern’s body slightly to throw more light across the road.

Unfortunately this was still not adequate as the thin spigot presented an obvious break in the flow of the lines of the whole

unit from column, bracket and into the lantern. Therefore the Z8591 range was developed which bulked out the spigot

entry, making it more of an integral part of the lantern, and offering a wide flat area onto which it would abut a bracket.

This design also changed the optical system of the lantern slightly by moving the lamp assembly from the pavement side to the road

side of the carriageway. This entry in the family also included a gear-in-head option, which extended the lines the lantern through the gear compartment

itself giving the lantern a unified feel.

The final design in the range was the Z8895 which restyled the canopy of the lantern, giving it a flatter, streamlined

appearance. But with the size of gear decreasing, and new lamp options appearing then this style of

lantern came to an end; and it was eventually superseded by the GEC Z8832 range.

|

Popularity

It was a popular lantern, second only to the Z8895 range. It was installed throughout the country.

Identification

Identification of the lantern is relatively easy. Other manufacturers made similar designs but the GEC version

was the bulkiest with the deepest style bowl.

Optical System

The primary optical system comprised of a single glass or plastic refractor bowl. In the case of glass it was specially designed

for the lantern and was held in position by a bowl ring. The plastic bowl option simply clipped in place without the requirement of a

bowl ring. The curved profile of the canopy, and its white painted interior, acted as a secondary optical system, reflecting light back which was emitted above the lamp.

Gear

The gear was mounted in an integral compartment which was part of the canopy of the lantern. Positioned behind the lamp compartment,

it was separated by a bulkhead and accessed via a separate hinged door.

The GEC Z8691 In My Collection

|

|

facing profile

This lantern was originally installed somewhere in the York area. The only change, after many decades of service, was

the yellowing of the polycarbonate bowl.

|

|

|

|

front profile

The bowl was held in position by a stainless steel clip, bowl ring and simple hinge. The bowl swung backwards towards

the pavement when opened. The position of the bowl hinge was a stipulation of BS 1788:1964 and it required

bowls to swing towards the road to prevent hitting the bracket. There is little chance of that happening with this lantern

due to the side of the gear compartment.

|

|

|

|

trailing profile

The lantern’s bowl and lamp canopy was tilted to allow extra throw of light across the road. The gear compartment featured a deep

mounting area which abutted against the bracket – especially concrete brackets – and so continued the line of the bracket.

|

|

|

|

canopy

The canopy of the lantern was slightly rounded. This ensured a large elliptical interior which aided the secondary optical system

of the lantern.

|

|

|

|

logo

Strangely, and unlike many GEC lanterns, the firm’s name wasn't embossed into the top of the canopy.

|

|

|

|

pedestrian view

The polycarbonate bowl was a GEC Z6818. Its function could be determined by “reading” the refractor pattern;

horizontal prisms on the sides to elevate and control the main beams; vertical prisms on the rest of the sides to spread the

light onto the road surface and back behind the lantern for roads and front gardens.

|

|

|

|

vertical

The base of the refractor bowl had simple parallel prisms to spread the light beneath the lantern. This

increased the size of the “light spot” or “head” beneath the lantern and prevented the formation of bright

spots on the road surface.

Two small screws allowed access to the gear compartment. The bottom of the compartment swung down towards the

pavement. The two larger screws held the ballast which was mounted on the other side.

|

|

|

|

interior #1

The interior of the lantern was extremely simple. The lamp holder was mounted pavement side allowing the connecting leads to simply

emerge from a hole in the side of the bulkhead from the gear compartment.

It was painted white to act as a secondary optical system so that light emitted above the lamp would be reflected back

down to the refractor bowl. It was slightly compromised by the extrusion of the top of the gear compartment which

created a large slot in the elliptical canopy.

|

|

|

|

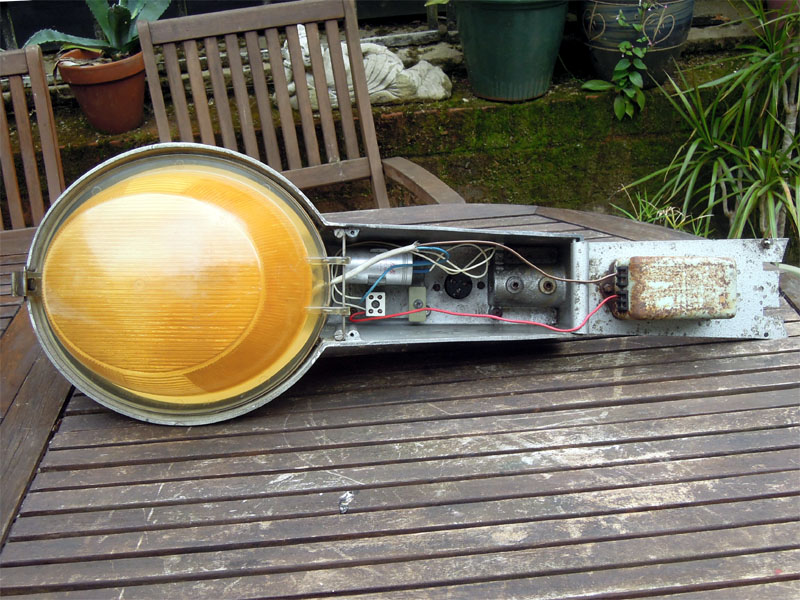

interior #2

Swinging the bottom door of the gear compartment open revealed the lantern's gear. A standard GEC

ballast was mounted to the top of the door, but it was now too rusted to read its model number. The power correction capacitor

was also by the GEC but it was too difficult to read any other information printed on it. Other components

included a terminal block and cable clamp.

|

|