|

GEC Z9484

Genre: Enclosed Horizontal Traverse Low Pressure Sodium Lantern

The low pressure sodium discharge lamp was developed by Philips in 1932. After two successful trial installations

(including the first low pressure sodium installation in the UK along the Purley Way, Croydon) the first commercial installation

was installed by Liverpool Council in 1933 using specially commissioned lanterns from Wardle.

The development of lanterns continued through the 1930s and accelerated when it was determined that the lampís brightness and

its long length made it less susceptible to glare. Lanterns with bare bulbs suspended over an overhead reflector (the so-called "seagull" lanterns)

quickly followed. Glass manufacturers were initially slow as the first plate refractors for low pressure sodium lamps didnít appear

until the end of the decade.

The advantages and disadvantages of low pressure sodium were readily debated, especially when an alternative (the medium and high

pressure mercury discharge lamp) was also available. The monochromatic light was considered especially useful for arterial

and traffic routes, the lampís shape cast a wide beam across the road surface, the light was also considered more penetrating

in foggy conditions and it was the most efficient light source being manufactured. However, the light was also considered

inappropriate for high streets, promenades, civic areas and residential streets and so some lighting engineers

restricted its use to traffic routes only. Therefore low pressure sodium became known as "the driversí lamp."

The arrival of plate glass refractors resulted in large lanterns made of metal frames enclosing heavy glass sheets.

These bulky lanterns continued to be made into the 1950s until being usurped by lanterns with plastic bowls and

machined or moulded plastic refractor plates. The lanterns were still large; the size dictated by the bulky

control gear, but their design and construction was becoming simpler.

The 1950s and 1960s saw huge improvements in the construction and efficacy of low pressure sodium. Early two-piece

designs (dubbed SO) were replaced by the one-piece, more efficient integral design (called the SOI). The development of

linear sodium (SLI) broke the one hundred lumens per watt barrier, lead to a radical rewriting of the British Standards

of street lighting and prompted the development of new families of streamlined lanterns. But it wasnít until the arrival

of a new heat-reflecting technology (called SOX) that a cheap family of extremely efficient bulbs became available.

The energy crisis of the 1970s saw a rethink in street lighting and lamp efficiency became dominant when fuel was both

in short supply and expensive. This saw the large scale removal of colour corrected high pressure mercury, fluorescent and

ancient tungsten lamps by low pressure sodium replacements. The old arguments that the smoky-orange lamps were inappropriate

for residential areas no longer applied. By the end of the 1980s, low pressure sodium was the dominant street lighting lamp used in the UK.

The use of low pressure sodium came under scrutiny again. High pressure sodium, finally developed as a viable technology in the

1960s, was coming of age and offered a compromise of slightly less efficacy with better colour rendering. Questions were

being asked about the physiology of the eye and visual adaptation under low lighting levels; previously the wavelength

of low pressure sodium had been deemed the most suitable, but research now suggested that the eye responded better to white

light. Concerns were raised about light pollution and the low pressure sodium lamp was seen to be the chief culprit

(although it was more to do with older non-cutoff and semi-cutoff optical designs rather than the lamp itself).

By the turn of the century, the age of low pressure sodium was seen as coming to an end. Research in white light technologies,

especially metal halide and a renewed interest in compact fluorescent coupled with the advantages of using white light at

low lighting levels, saw the end of the low pressure sodium lampís dominance. Its use was discouraged in the specifications,

lantern manufacturers started to wind down their production and bulb manufacturers followed suit.

By the end of the first decade of the 2000s, low pressure sodium was in stark decline, and less and less of the UKís

streets were being lit by its characteristic orange glow.

Name: GEC Z9484

Date: Early 1960s - Early 1980s

Dimensions: Length: 23½", Width: 5¾", Height: 5¾"

Light Distibution: Semi Cut-Off (BSCP 1004:1963)

Lamp: 35-55W SOX

History

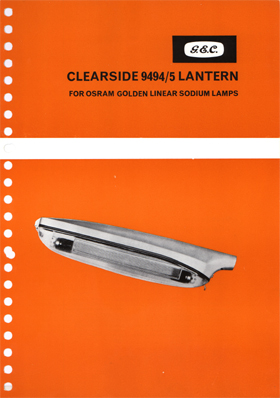

GEC 9494/5 catalogue

|

The GEC Z9494 family of lanterns was introduced in the early 1960s. It was part of a range of new

lanterns which were designed to utilise the new SLI low pressure sodium bulb and conform to the new British Standard Code

of Practice for street lighting: BS CP 1004:1963.

The lanternís sleek lines were also made possible by the decision to forgo a gear-in-head option which had made

previous designs so bulky and boxy. The design was effectively a thin elongated extruded oval with the line of

the perspex bowl matching the curve of the aluminium alloy canopy. A singular clip was provided at the spigot end

of the lantern and the bowl carried the rubber gasket.

The optical system was designed for the tubular 60W SLI/H bulb and comprised of two Perspex refractor plates glued

to the Perspex refractor bowl to give a semi-cut off light distribution (in accordance with CP 1004:1963).

As the popularity of the SLI/H bulb started to decline, the GEC offered a version of the lantern for SOX lamps (the Z9484).

This simply required the removal of the two bi-pin connectors and the addition of one porcelain lamp holder and a lamp

steady. The design of the bowl also changed and a polycarbonate version was offered with the refractor plates machined or

moulded into sides.

The lantern was discontinued in the early 1980s. The GEC already had an extremely popular low pressure sodium

gear-in-head range of lanterns (the Z9530 range) and the Z9494 range was probably considered an expensive, historical and

redundant luxury.

|

Popularity

The lantern was very popular and huge numbers of the SLI and SOX models were installed

throughout the country. The obsolescence of SLI did nothing to diminish its popularity

and itís believed many lanterns were converted in-situ to SOX rather than be replaced.

The two bowl options (Perspex with glued refractor plates and Polycarbonate with moulded refractor plates) seem to be equally common.

Identification

The lantern is extremely distinctive and easy to distinguish from the boxy, deep-bowled lanterns made

by competitors. The lantern also has "GEC Made In England" cast onto the canopy. It's possible it originally had an

identification sticker inside the canopy but this has long gone

Optical System

The primary optical system comprised of two plate refractors positioned either side of the bulb. As the low pressure

sodium lantern already casts a wide beam in azimuth, the horizontal refractors simply alter the flux elevation by

fashioning two main beams in a semi-cut-off distribution (in accordance with CP 1004:1963).

The interior of the canopy is painted white. This secondary optical system reflects any flux emitted above

the horizontal back toward the ground.

The exterior of the bowl is smooth to facilitate easy cleaning.

Gear

The lantern was never designed to carry gear Ė which is why the lantern is so small and sleek.

However, the Z9495 carried a starter switch for the 60W SLI/H bulb.

|

|

|

facing profile

This lantern was rescued from a skip at Brighton Council. It was still attached to an enormous 6' length of bracket when it was dragged out. Unfortunately

this means the original location of this lantern will never be known.

|

|

|

|

front profile

Brighton Council had maintained the lantern well and the grub screws holding the lantern to the bracket were still greased. Despite some flaking

of the white paint inside the canopy, and the addition of a P42 two-part photocell, the lantern was in good condition.

|

|

|

|

trailing profile

The photo-cell was removed along with all the internal components. The hole was filled and the lantern was resprayed: aluminium on the exterior and white on the interior.

The internal components were then put back in the lantern.

|

|

|

|

canopy

The polycarbonate bowl was also in good condition with only a slight yellowing. The gasket (oddly attached to the bowl and not the rim of canopy) was

also in excellent condition.

|

|

|

|

logo

Like many GEC lanterns, the lantern has the makers name cast into the canopy of the lantern. They often included an

identification sticker inside the lantern as well, but if one was ever fitted, it has long since disappeared.

|

|

|

|

pedestrian view

I fitted the lantern with a 35W SOX lamp although it would have accommodated a 55W SOX lamp. It was originally designed for a 60W SLI/H lamp.

It still remains one of the sleekest low pressure sodium lanterns ever developed.

|

|

|

|

vertical

This vertical view clearly shows how thin the lantern is and the two halves of the polycarbonate bowl.

|

|

|

|

open bowl

Opening the bowl allows the interior of the lantern to be seen. The minimal interior includes the bulb holder assembly, lamp steady, terminal block and

cable cleat. The lugs in the interior were originally designed to hold the bi-pin connectors for the 60W SLI/H bulb which is why the lamp steady

needs a long run-back to hold the 35W SOX lamp.

|

GEC Z9484: As Aquired

This shot shows the lantern after it was removed from its bracket - the grease around the grub screws can still be seen. I'd also removed the

P42 two-part photocell in this shot.

|