|

Philips SGS201

Genre: Enclosed Horizontal Traverse High Pressure Sodium Lantern

As soon as the low pressure sodium lamp (LPS) was developed, the race was on to develop a version which would run at high pressure (HPS).

The research was stimulated by the prospect of the spectral broadening of the light emitted from such a bulb and

the improved colour rendering which would result. However the development was hampered by the lack of a translucent material which

could withstand the chemical attack of sodium vapour at extremely high temperatures and pressures.

It wasnít until the early 1960s that General Electric (GE) cracked the problems,

closely followed by the GEC and Philips. A prototype high pressure sodium lamp was

exhibited at the APLE's annual conference in 1963, but it wasnít until 1966 that the GEC erected an experimental installation

along East Lane, Wembley (which, incidentally, also saw the first experimental medium-pressure mercury installation over thirty years before).

The first commercial installation in the UK was erected along the Southend ring road, but it was the City Of London who gained the most

recognition by beginning a radial upgrading of all their lighting to high pressure sodium in 1967. As the early HPS bulbs were designed

to be retrofitted into existing mercury installations, the lanterns chosen by the City Of London were slightly modified versions of

existing mercury lanterns.

The first true HPS lanterns (designed from scratch with the new light source in mind) appeared in the late 1960s and early 1970s. All

these lanterns utilised a cross-over design: whilst this was an adaption of existing mercury lanterns, it also moved the lamp up into

the lanternís canopy (where it could not be directly viewed by drivers, thus minimalising the glare) and allowed designs to cater for

both cut-off and semi-cut-off.

Wider adoption of high pressure sodium was stalled by the energy crisis, as it couldnít match the efficiency of its low pressure sodium brother.

Councils, believing in the simple maximum lumens per watt paradigm, replaced existing tungsten, mercury and fluorescent schemes by

low pressure sodium. So it wasnít until the 1990s that HPS started appearing in greater quantities.

With its efficiency between high pressure mercury and low pressure sodium, HPS became even more attractive when LPS was finally exorcised

from the British Standards of street lighting (as it didn't provide an adequate colour rendering). However, it didn't remain as first choice for

new and replacement lighting schemes for long. Renewed interest in fluorescent (from compact fluorescent sources), the emergence of affordable

metal halide and the possible introduction of LED have all questioned the automatic selection of high pressure sodium for schemes.

Therefore by the end of the first decade of the new century, high pressure sodiumís position as the natural choice for street lighting

was coming under pressure.

Name: Philips SGS201

Date: Early 1970s -

Dimensions: Length: 520mm, Width: 290mm, Depth: 190mm

Light Distibution: Cut-Off

Construction: To BS 4533

Lamp: 35W SOX, 80-125W MBF/U, 50-70W SON

History

|

|

The Philips SGS 201 was introduced amongst a host of new lanterns in mid 1975. Specifically designed

for the newly introduced High Pressure Sodium (HPS) lamp, it was also available in options for high pressure mercury and low

pressure sodium (all of which used the same canopy and gear compartment, but used different gear).

It shared many design traits with its competitors (such as the Thorn Beta 79). The bulb and gear

were housed in two separate compartments, the optics were based on a cross-over reflection system, and the canopy was made from moulded GRP.

Significant differences from other lanterns were the introduction of an entirely curved and figured optical system (whilst the competitor

lanterns used separate side and over reflectors) and an option for either post-top or side entry mounting. (Both these features would

become standard for all lantern types many years later).

The lantern is still being made today and is an important part of the Philips range.

|

Popularity

The lantern is extremely popular and can be found installed in many places throughout the UK.

Identification

Owing to its popularity, it is easily identified as itís so often seen! However, one unique feature is the gear tray

cover which slots over the top of the lantern (and has a dog-legged side which engages with the canopy). Competitor

lanterns of the time had gear trays that unscrewed and swung open from the base of the lantern. (It's designed this way because

the lantern can also be mounted post-top by rotating the spigot, so a hinged lower gear tray isn't an option).

Optical System

A formed polished metal reflector comprises the primary optical system. This totally encases the top half of the

bulb and produces a cross-over flux distribution which results in the cut-off distribution.

Gear

The gear is housed in its own gear compartment. This has a lower IP rating than the lamp compartment and is access

is achieved by unscrewing two screws and lifting the top of the canopy. As access is through the top of the lantern,

no separate gear tray or hinges are required.

The components are screwed into the lantern canopy and include the main lamp choke, a power correction capacitor and an ignitor.

The Philips SGS201 In My Collection

|

|

facing profile

This lantern was originally installed somewhere in Northamptonshire and was obtained from fellow collector Darren.

|

|

|

|

front profile

The bowl is held in position by a single stainless steel clip.

|

|

|

|

trailing profile

Two characteristics of the lantern can be seen from this angle. The side profile of the bowl is relatively small when compared against

the depth of the canopy; competititor lanterns had much deeper bowls. The gear tray also lifts of from the top of the lantern and

has a distinctive "dog leg" where it turns at 90° to travel along the lip of the canopy.

|

|

|

|

canopy

The canopy is smooth and featureless with the exception of a photocell. Another characteristic of the lantern is the spigot

which can be rotated down so the lantern can be fitted as a post-top lantern.

|

|

|

|

logo

Unlike many lanterns of their range, Philips chose not to emboss their name and logo on the lantern's canopy.

|

|

|

|

pedestrian view

This classic view clearly shows the reflector which encloses the entire upper hemisphere around the bulb. (Competetitor lanterns

often only use two curved side reflectors which a secondary, smaller over-reflector). The spigot assembly can also be clearly

seen where the spigot can be rotated down into a post-top position.

|

|

|

|

vertical

The bowl is simply clear and doesn't carry any additional refractors.

Additionally, a small sticker mounted on the base of the gear compartment, gives manufacturer, lantern, bulb and

voltage requirements.

|

|

|

|

interior #1

The reflector fills the entire bulb compartment. No light flux emitted above the horizontal is allowed to escape into the

canopy of the lantern.

|

|

|

|

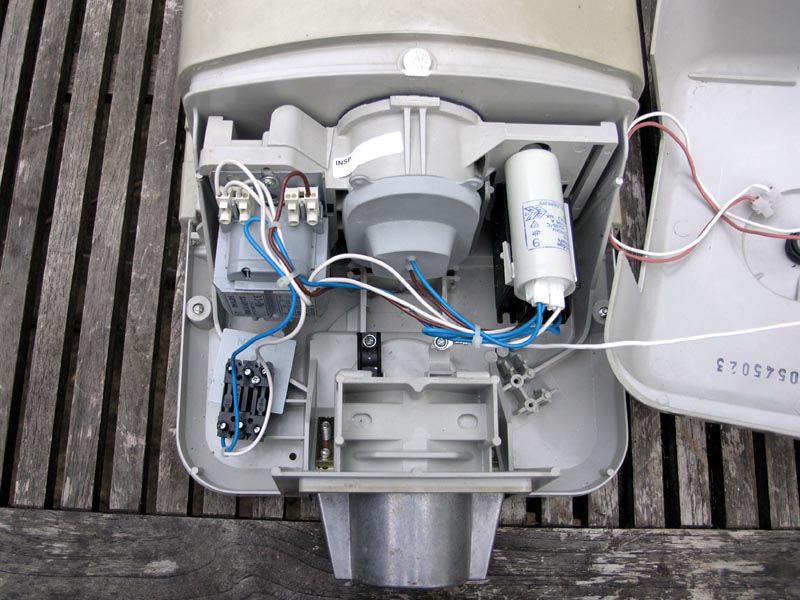

interior #2

The gear compartment is small and cramped because a third of the space is required for the spigot assembly. The choke

(a Philips BSN 50L427 ITS for 50W SON lamps) is mounted against one side of the gear compartment wall whilst the

power correction capacitor (a Cambridge Capacitor design rated at 9uF and dated 2005) is mounted above

the ignitor (a Philips SN 67) on the opposite side. There is also space for a terminal block and earth connections.

|

Philips SGS201: Night Burning

Philips SGS201: As Aquired

Now becoming a popular lantern on the residental streets of the UK, this 50W SON-T SGS201 was originally installed somewhere on the streets of Northampton.

It was obtained from fellow collector Darren.

|