|

REVO C13721/T

Genre: Enclosed Horizontal Traverse Low Pressure Sodium Lantern

The low pressure sodium discharge lamp was developed by Philips in 1932. After two successful trial installations

(including the first low pressure sodium installation in the UK along the Purley Way, Croydon) the first commercial installation

was installed by Liverpool Council in 1933 using specially commissioned lanterns from Wardle.

The development of lanterns continued through the 1930s and accelerated when it was determined that the lampís brightness and

its long length made it less susceptible to glare. Lanterns with bare bulbs suspended over an overhead reflector (the so-called "seagull" lanterns)

quickly followed. Glass manufacturers were initially slow as the first plate refractors for low pressure sodium lamps didnít appear

until the end of the decade.

The advantages and disadvantages of low pressure sodium were readily debated, especially when an alternative (the medium and high

pressure mercury discharge lamp) was also available. The monochromatic light was considered especially useful for arterial

and traffic routes, the lampís shape cast a wide beam across the road surface, the light was also considered more penetrating

in foggy conditions and it was the most efficient light source being manufactured. However, the light was also considered

inappropriate for high streets, promenades, civic areas and residential streets and so some lighting engineers

restricted its use to traffic routes only. Therefore low pressure sodium became known as "the driversí lamp."

The arrival of plate glass refractors resulted in large lanterns made of metal frames enclosing heavy glass sheets.

These bulky lanterns continued to be made into the 1950s until being usurped by lanterns with plastic bowls and

machined or moulded plastic refractor plates. The lanterns were still large; the size dictated by the bulky

control gear, but their design and construction was becoming simpler.

The 1950s and 1960s saw huge improvements in the construction and efficacy of low pressure sodium. Early two-piece

designs (dubbed SO) were replaced by the one-piece, more efficient integral design (called the SOI). The development of

linear sodium (SLI) broke the one hundred lumens per watt barrier, lead to a radical rewriting of the British Standards

of street lighting and prompted the development of new families of streamlined lanterns. But it wasnít until the arrival

of a new heat-reflecting technology (called SOX) that a cheap family of extremely efficient bulbs became available.

The energy crisis of the 1970s saw a rethink in street lighting and lamp efficiency became dominant when fuel was both

in short supply and expensive. This saw the large scale removal of colour corrected high pressure mercury, fluorescent and

ancient tungsten lamps by low pressure sodium replacements. The old arguments that the smoky-orange lamps were inappropriate

for residential areas no longer applied. By the end of the 1980s, low pressure sodium was the dominant street lighting lamp used in the UK.

The use of low pressure sodium came under scrutiny again. High pressure sodium, finally developed as a viable technology in the

1960s, was coming of age and offered a compromise of slightly less efficacy with better colour rendering. Questions were

being asked about the physiology of the eye and visual adaptation under low lighting levels; previously the wavelength

of low pressure sodium had been deemed the most suitable, but research now suggested that the eye responded better to white

light. Concerns were raised about light pollution and the low pressure sodium lamp was seen to be the chief culprit

(although it was more to do with older non-cutoff and semi-cutoff optical designs rather than the lamp itself).

By the turn of the century, the age of low pressure sodium was seen as coming to an end. Research in white light technologies,

especially metal halide and a renewed interest in compact fluorescent coupled with the advantages of using white light at

low lighting levels, saw the end of the low pressure sodium lampís dominance. Its use was discouraged in the specifications,

lantern manufacturers started to wind down their production and bulb manufacturers followed suit.

By the end of the first decade of the 2000s, low pressure sodium was in stark decline, and less and less of the UKís

streets were being lit by its characteristic orange glow.

Name: REVO C13721/T

Date: Early 1950s - Mid 1960s

Dimensions: Length: TBA, Width: TBA, Height: TBA

Light Distibution: Non Cut-Off (BSCP 1004:1952)

Lamp: 35W SOX (originally 60W SO/H)

History

REVO were one of the dominant street lighting manufacturers of the post-war period. From their

manufacturing base in Tipton, their columns, brackets and lanterns were installed in quantity throughout the UK as well as the world.

The REVO C13720 range was their first low pressure sodium lantern to utilise an entire Perspex plastic bowl.

It replaced the earlier Silvergold series, a range developed immediately after the war, which still used metal frames

to support bulky glass refractor panels. The REVO C13720 utilised the same canopy as the new bowlís shape

matched that of its predecessor. However, a novel new feature was the dimpled, figured bowl which diffused the flux at either end

of the lantern. (This was a clear departure from the Silvergold series, which blanked off these areas).

A family of lanterns were produced with several options: four different sizes were made (from the smallest 60W SO/H through to the largest

140W SO/H model); with two different mounting options (top or side entry); and the optional provision of gear-in-head.

This range of lanterns was never given a name, although an early advert referred to them as Silvergolds, suggesting

REVO toyed with retaining the name of the predecessor.

The lantern was still being produced well into the 1960s, but the appearance of more streamlined gear, and the requirement

for smaller, cheaper non-gear options prompted REVO to produce replacements. The Sol DíOr

range was the immediate descendant and retained the now characteristic figured bowl but lacked gear; so it was the Lucidor

range which finally replaced it completely in the product line.

Popularity

The lantern was extremely popular for main road use with the lanternís popularity only being eclipsed by that of

lanterns produced by the GEC. Side road versions were rarer, but this was more to do with lighting engineers

preferring whiter light sources for residential streets than any problems with the lantern itself.

Identification

The lanternís rather large, squashed appearance makes identification extremely easy. Furthermore, the large dimples

on the bowl are also a notable characteristic of the range (but this feature is also shared by the Wardle Atholl

so it canít be considered unique). "REVO" is also cast into the exterior of the canopy.

Optical System

The primary optical system is designed to cast a non-cut-off non-axial asymmetric distribution in accordance with BSCP 1004:1952.

Two refractor plates glued to the sides of the Perspex bowl perform this function. The rest of the bowl is of figured

formation which acts as a diffuser, distributing evenly the rest of the flux not forming the main beams. A secondary

optical system comprises of a staggered, sea-gull or flat white-enamelled over-reflector (various lanterns differ) which

redirects flux emitted above the horizontal back to the street surface.

Gear

Some versions of the lantern carry gear. This is mounted on the opposite side of the white over-reflector and comprises

a leak transformer, power correction capacitor and terminal strip. A water drip-shield is also installed over the bracket

entry hole in top-entry models to prevent condensating water in the bracket dripping onto the gear itself.

The REVO C13721/T In My Collection

|

|

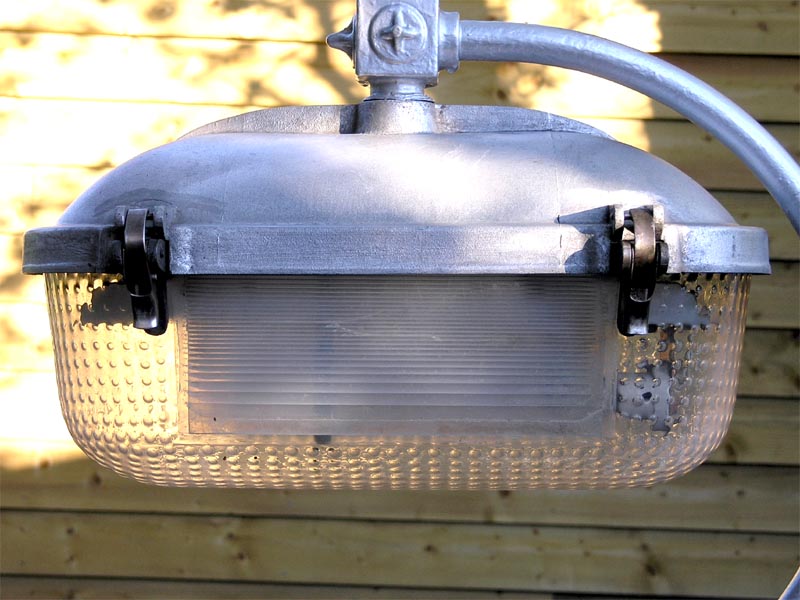

facing profile

This REVO C13721/T enclosed low-pressure sodium lantern and

REVO B6024 swan neck bracket were purchased from the

company demolishing Cane Hill Mental Hospital in 2009. It was installed on a REVO Moseley

column and was part of an installation lighting the hospitalís perimeter road.

|

|

|

|

front profile

After over forty years of service, including a decade standing idle on the derelict site, the lantern body was

in good condition but the original Perspex bowl was almost completely opaque with a large hole

smashed into the front.

|

|

|

|

trailing profile

A new bowl was acquired from a fellow collector, but this was missing a refractor plate. Therefore a complete

refractor plate was removed from the original bowl and glued into the replacement therefore making a complete example.

The original bowl had a slightly different design to its replacement. The refractor plates featured extrusions at the top

where they were bolted to the bowl using the same holes as the bowl securing screws. The replacement bowl used rectangular

refractors which were glued to the bowl.

Furthermore the bowlís figured formation i.e. the dimples, were much more pronounced on the original bowl.

|

|

|

|

canopy

The lanternís aluminium canopy scrubbed up well after work with a wire brush, Brillo pad, CIF cleaner and several

scrubs. The top entry version of the lantern also featured two small supporting ribs along the top of the lantern.

|

|

|

|

logo

"REVO" and "Made In England" were cast into the top of the canopy. No other identifying marks were found.

|

|

|

|

pedestrian view

The bowlís angled sizes were designed to position the refractor plates in the ideal position with

respect to the bulb. The rest of the bowl area was covered in dimples which were designed to diffuse

the rest of the light flux and spread it evenly on the area below the lantern.

|

|

|

|

vertical

The dimples continued over the base of the bowl. This would've ensured that no bright patches would've been cast beneath the

lantern onto the road surface below.

|

|

|

|

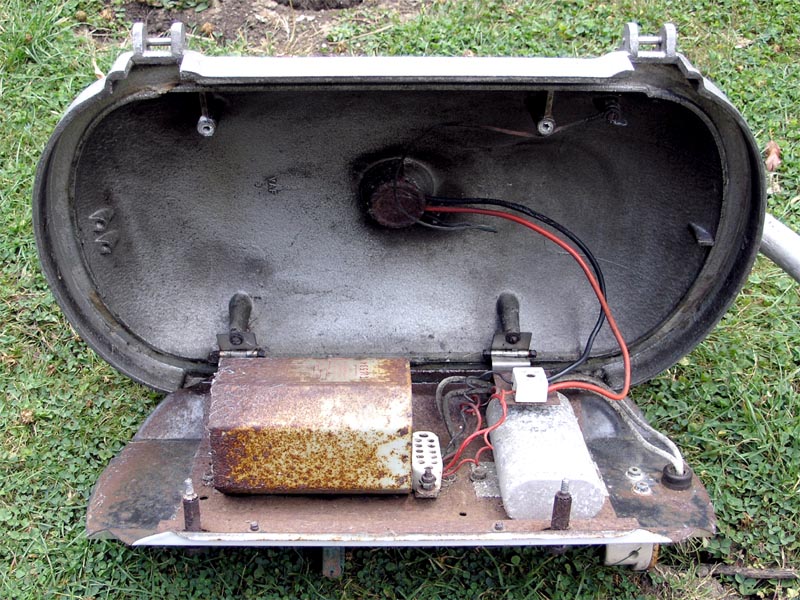

open bowl

This shot was taken during restoration when the original bowl was removed. Here the stepped white-enamelled over-reflector

acts as a secondary reflector and also doubles up as the gear tray (hence the stepped formation forming a flat area where the

gear can be fixed).

Note the holes for a second bulbholder position. I believe this was the location for the bulbholder when the smaller 45W SO/H bulb

was in use; therefore the only difference between the C13720 and C13721 was the location of this bulbholder assembly.

The original asbestos wiring from the bulbholder to the terminal strip was in good condition and was left in-situ.

|

|

|

|

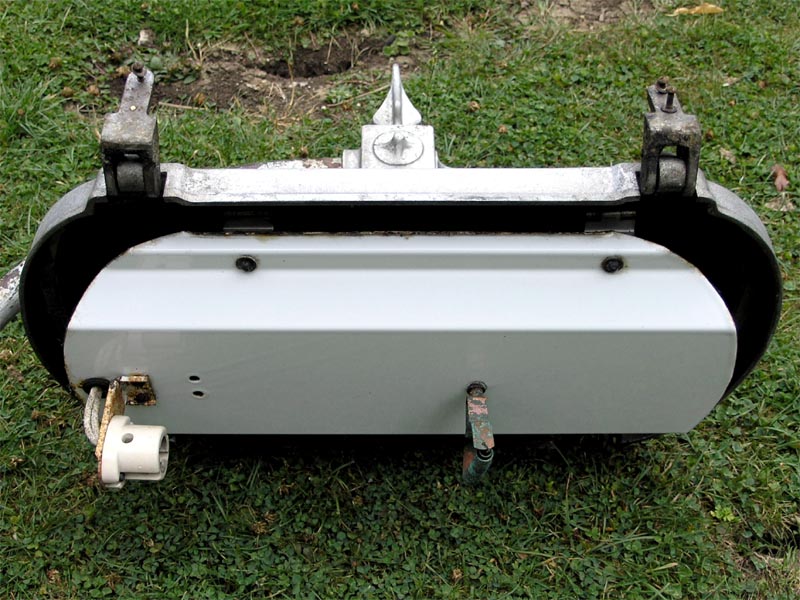

open bowl

Two screws held the gear tray in position. When loosened these allow the gear tray to swing down supported by two hinges

on the opposite site of the lantern.

The gear had rusted after over forty years of use but still worked when tested. The leak transformer was made by Philips

(under license) but the manufacturer details and date had long corroded from the power correction capacitor.

The lantern also retained its drip shield which was secured to the canopy just above the hole for the swan neck.

This collected any water which dripped from this opening due to condensation in the swan neck. It wouldíve prevented water dripping

on the leak transformer and terminal strip mounted on the gear tray just below it.

|

The REVO C13721/T As Aquired

This lantern and its swan neck originally stood on the perimeter road of the legendary

Cane Hill Mental Hospital in Coulsdon, South London. It was purchased from

the demolition contractors in 2009 when the majority of the derelict hospital was pulled down.

Exterior lighting for the hospitalís road network, paths and exterior courtyards was provided by REVO.

Itís thought that the hospitalís works manager probably asked Croydon Council for advice for suitable exterior equipment

as Croydon used both REVO and the GEC for their lighting.

REVO 13271/T low pressure sodium lanterns were installed along the perimeter road on

ornate REVO B6024 swan-neck brackets

and REVO Moseley columns. Lesser service roads and paths

were also lit by REVO 13271/T lanterns but mounted on Stanton 7

concrete columns with arched brackets. In other areas, including exterior courtyards and footpaths, a variety of

REVO Magnalite lanterns were installed.

Unfortunately the bowl was peppered with air-pistol holes and one end was smashed away. This was the only part of the lantern which required

replacement.

Fellow urban explorer Marlon Bones took this shot of the fire-damaged Vincent/Vanbrugh in late 2007 and also

included my REVO 13271/T lantern on the perimeter road. Another collector attempted to rescue the column but

it snapped off at the door when it was pulled from the ground.

|