|

Urbis Aramis 1A

Genre: Globe lantern

Since the earliest days of lighting, the glare from a point light source could always be

softened and reduced by means of a diffusing globe or sphere. Although the gentle light

produced by the early gas lanterns never merited any diffusing glass, the arrival of

the arc lamps necessitated huge opaque glass globes required to soften and spread

the piercing light of the electric arc.

When the incandescent bulb arrived, some exterior lanterns offered a choice of either

clear flint glass or opaloid glass, but the function of the lantern was still to protect

the bulb(s) and provide an even symmetrical distribution of light. It wasnít until the 1920s,

the scientific foundations of street lighting, and the development of directional lanterns,

that the globe lantern fell from favour as a general street lighting lantern.

It was relegated to the back of catalogues as a "decorative" lantern. By the 1930s,

the globe lantern was pushed into service on elegant columns and brackets, as a focal

point on bridges, boulevards, public spaces, parks and other open areas. Its optical

control was limited to just its diffuser bowl.

During the austere 1950s, it had all but disappeared from the manufacturers catalogues

and it certainly didnít fire the imagination of the design conscious 1960s. (Its two main uses

being limited to the orange globes of Belisha Beacons and the white sphere of the refuge island lantern).

But, it reappeared in the 1970s; companies such as the GEC and Phosco

placed their street lighting optical systems within the globe itself, thus embellishing the

lantern with modern street lighting optics whilst maintaining its classical daytime appearance.

Other companies also jumped on the bandwagon, but simply returned to the old idea of placing a

bare lamp in a spherical diffuser.

The spherical lantern is still popular, but todayís push for ever more efficient lanterns and

strict control of light means the upper hemisphere of the lantern isn't illuminated in modern

versions. Therefore its daytime appearance doesn't match its night apperance. It remains

to be seen if authorities will continue favouring this version of the globe lantern.

Name: Urbis Aramis 1A

Date: Circa Mid 1980s -

Dimensions: Length: 672mm, Height: 439mm

Light Distibution: SealSafe 1200, 1312, 1543 system. Conforms with BS 5489-1 / EN 13201.

Lamp: 50-150W SON (metal halide, mercury vapour and white sodium also available).

History

It isnít known when the Urbis Aramis range of lanterns entered production,

but a guess of the 1980s wouldnít be far off as the lantern featured Urbisí SealSafe

reflector technology. Additionally the banded sphere lantern type became fashionable again in the

1980s, appearing in high streets, shopping centres, car parks and other large, civic areas.

It isnít known when the Urbis Aramis range of lanterns entered production,

but a guess of the 1980s wouldnít be far off as the lantern featured Urbisí SealSafe

reflector technology. Additionally the banded sphere lantern type became fashionable again in the

1980s, appearing in high streets, shopping centres, car parks and other large, civic areas.

Initially the lantern was called the Aramis Sealsafe thus emphazing the use of the

reflector optical system.

Urbis provided three basic variants of the lantern: the Aramis 1 series

featured a round lower globe; the Aramis 2 range had a flattened dish bowl; and

the lone Aramis 3 was fitted with flattened glass.The ranges were expanded

with several different shaped upper hemispheres, and the lantern bodies could be specified in

any colour from the British Standard or RAL range.

The earlier lanterns (such as the Aramis 1A in my collection) featured

polycarbonate upper globes. These could be illuminated by an optional extra called

the Top Glow - a hole made in the top of the Sealsafe reflector, sealed

with a diffuser. This option was removed in later lanterns as they used spun aluminium canopies.

Popularity

As it is primarily decorative, the Urbis Aramis is limited

in its application, although it appears to be widely installed where decorative lanterns are

required.

Identification

No external Urbis logos can be found on the lantern (although there's plenty

of stickers inside the lantern canopy to positively identify it). But the lantern can be

identified by its metal band which is slightly thicker at the bracket end of the lantern, tapering

slightly as it reaches the other end of the lantern. Other competitors feature either

bands of uniform thickness or different shaped bowls.

Optical System

The lanterns optical systems were based on the SealSafe 1200, 1312 and 1543 reflectors. These were

designed for 50-150W SON-T bulbs, although the lantern could also take metal halide, mercury vapour

and/or white sodium lamps.

The Urbis Aramis 1A In My Collection

|

|

facing profile

Darren gave me this lantern which was installed somewhere in the

Northampton area. It was in extremely good condition after several years of service.

|

|

|

|

front profile

Despite some peeling of the black paint on the underside of the bracket support,

the lantern had weathered the years well.

|

|

|

|

trailing profile

The lantern body comprises a flat, circular piece of aluminium around which is

attached a metal band. A separate component for spigot mounting is bolted

to the back of the lantern assembly and two plastic diffuser bowls are screwed

to either side of the body. The SealSafe optic and gear tray are

mounted in the upper half of the lantern with the lower hemisphere free for light distribution.

|

|

|

|

canopy

The top of the lantern is covered by a plastic diffusing sphere. It is held in place

by three Allen keys. Any rainwater collected in the rim and will flow down to the spigot

attachment where it drains away through four holes drilled through the lantern body.

|

|

|

|

canopy: lit

The top sphere is not just a decorative feature. When powered on, a small amount of

flux is emitted inside the top hemisphere to gently illuminate the top of the lantern.

A stainless steel reflector mounted inside the top of the globe redirects the flux back

out through the sides of the bowl.

|

|

|

|

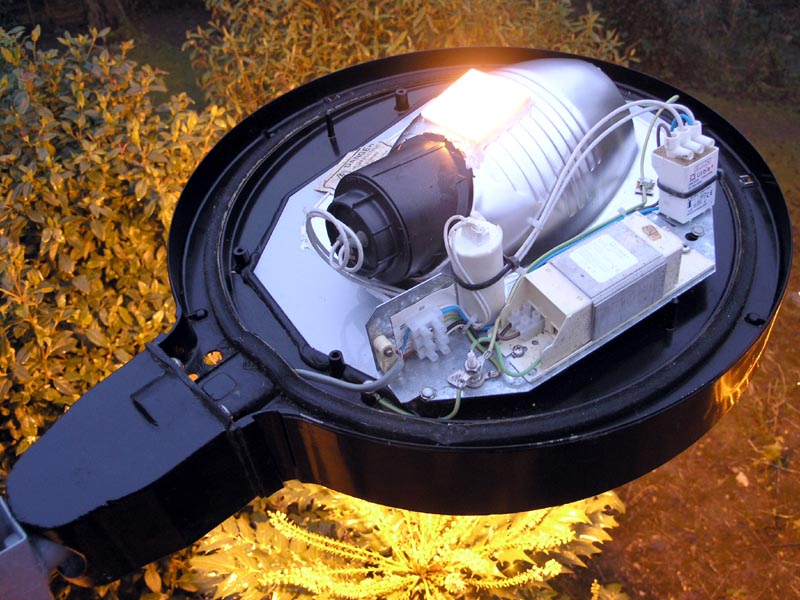

canopy: open

With the top cover removed, the modification to the SealSafe 1200 optic can be seen.

A hole has been made in the top of the optic with a square diffuser panel stuck over the top.

This allows a small amount of light to illuminate the top half of the lantern thus giving

the impression of an entirely illuminated globe of light. This was the optional

Top Glow feature provided by Urbis.

Note how this is an older version of the lantern. The gear tray is bolted in place

(in later versions it is removable) and the ballast and ignitor feature the old Urbis logo.

Additionally modern versions of the lantern have spun aluminium canopies and don't emit light from

the upper hemisphere - so the Top Glow feature was withdrawn.

The ballast is an Urbis HSG07024521 (70W 1A HPS) thermal cut-off unit

and the ignitor is an Urbis PXE070255 for 35-70 HPS lamps.

The markings on the capacitor have rubbed off over the years and cannot be read.

|

|

|

|

canopy

This view of the lantern clearly shows the overhead reflector fitted inside the

bowl and the three allen screws holding the top bowl firmly in place.

|

|

|

|

vertical

In this view, the four holes to allow water drainage can clearly be seen.

|

|

|

|

pedestrian view

The bottom globe is stuck in position to maintain the high IP rating of the optical chamber.

Bulb changing is therefore achieved by removing the top hemisphere and accessing the bulb

by releasing it from the SealSafe optic (itís similar to a bayonet connector

and just requires a twist to remove it.)

The lantern is essentially a SealSafe optical system enclosed within a diffusing sphere.

|

Urbis Aramis 1A - During Restoration

The lantern had been stored in the garden for a couple of years but wasn't too dirty. From the

exterior, the lantern didn't require much restoration and the interior appeared clean and dry.

Removing the three allen keys allowed the top hemisphere to be removed. This revealed the gear tray

(Urbis gear for 70W SON lamp) and the top of the SealSafe optic.

Whilst the bottom hemisphere appeared to be held in place by three Philips screws which were easily

removed, the plastic bowl wouldn't budge. I believe it's been glued in place, thus ensure the

IP rating of the SealSafe chamber.

Access to the bulb is by twisting the bulb holder (which works like a large bayonet connector).

After another clean, the lantern was already looking much better.

The next job was to get the old bracket off the lantern. (Darren simply sawed through

the bracket when he removed the lantern leaving a stub attached). The allen grub screw nearest the

lantern unscrewed with lots of penetrating oil and using a pipe to add leverage to the allen key; the

furthest one wouldn't budge and I ended up bending the allen key.

Heat didn't work either so there was nothing for it - I drilled it out. Once removed, the bracket stub

simply pulled out.

The remaining stub of the grub screw was removed using a cold chisel and hammer. There was still some

bits left in the thread of the hole, so this was removed using a tap-and-die set to cut the

threads.

The lantern was then mounted on a bracket to have its pictures taken. Whilst it was still partly

disassembled, it was a good opportunity to test it and make sure it all worked. Which it did.

|