|

Specification Clearmain 8427

Use

Main road lighting. For the best results the spacing/mounting height ratio should be 3:1.

Lamp

250W or 400W Osram MBF/U colour corrected mercury lamp.

Mounting

The Z8427 side entry lantern requires not less than 4 in. of horizontal unthreaded

1.1/4 in. B.S.P.

Lampholder

Porcelain G.E.S. wired with heat-resisting insulated wire to a porcelain terminal block.

Lantern Body

The lantern body consists of two main parts, a die-cast light alloy canopy and a pressed

aluminium main body. The lantern canopy carries the clamping bolts, porcelain terminal block

and lampholder. An earthing screw and porcelain cable cleat are provided.

Hinged to the lantern canopy and secured, when closed, by a quick release toggle

catch, is the main body pressing. A moulded "Perspex" dish held in an aluminium rim

to the main pressing makes the lantern totally enclosed.

Optical System

The lantern optical system has been designed to produce a cut-off distribution when

using the 250W or 400W MBF/U lamp. The contour of the inside surface of the body pressing

has been very carefully designed to make the maximum use of the light from the lamp. Each

side of the body forms a long curved reflector producing the required crossover

distribution. The ends and top of the body pressing are "figured" to contribute and

redirect light in the upper hemisphere back on to the road surface.

Weathering Finish

The alloy used is especially selected for its resistance to corrosion. Further protection

is obtained by the use of anodising, a pretreatment primer and stove enamel top coat.

|

| The lantern with the die-cast light alloy canopy released from the pressed aluminium

main body showing the lamp mounting and bracket clamps. |

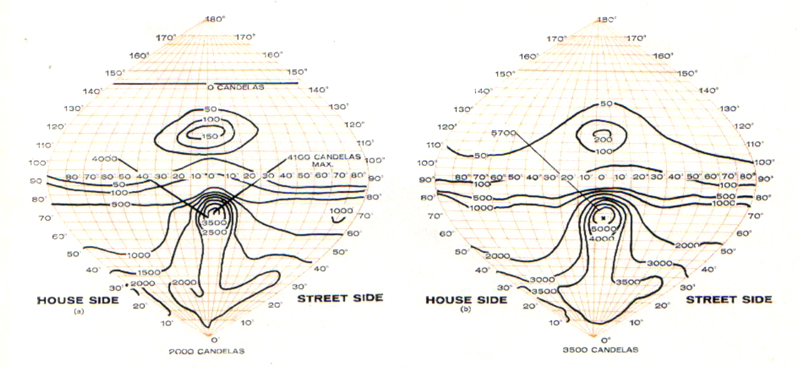

The iso-candela diagrams are based on an average lamp light output through life from:

(a) 250W Osram mercury type MBF/U lamp (10,000 lumens average).

(b) 400W Osram mercury type MBF/U lamp (17,500 lumens average).

| 250W | 400W |

| Directional intensity ratio | 3.48:1 | 2.9:1 |

| Light above horizontal | 2% | 2% |

| Light output ratio | 75% | 75% approx |

| Lumens in the lower hemisphere | 7,400 | 12,750 |

Light distribution data are given for the guidance of the lighting engineer and represent the

average results of laboratory tests on a number of lanterns taken at random from stock.

The data are based on the lamp characteristics stated; if the latest lamp efficiency is different,

the candela or lumen values should be calculated in direct proportion to the relative lamp

lumens.

Lantern weight: 16lb (7.26 kg).

|