|

Specification Clearmain 8430

Use

Main road lighting; the lantern is designed for mounting at 25 ft. (7.62 m) and at spacing

120 ft (36.58 m) optimum, but can be used up to 150 ft. (45.72 m) maximum; road

width up to 30-40 ft (9.14 - 12.19 m).

Lamp

250W or 400W Osram mercury type MA/V lamp.

Mounting

Side entry. The lantern requires not less than 4 in. of horizontal unthreaded 1.1/4 in.

B.S.P. When fully home two 7/16 in. dia. Allen type grub screws grip the barrel. Water

running along the bracket arm is prevented from entering the lantern by a water baffle.

Lantern Body

Die-cast aluminium alloy. The body carries the reflectors, lampholder, terminal block,

heat resisting insulated wiring, lamp-steady, reflector plate, and universal magnetic

deflector. An earthing screw and porcelain cable cleat are provided.

Lampholder

Porcelain G.E.S. wired with heat-resisting insulated wire to a porcelain terminal block.

Over-Reflector

Immediately over the lamp is a hinged, non magnetic reflector. This can be lowered by

releasing the screw holding it, and gives access to the bracket entry and terminal

block. The reflector serves the dual purpose of reflecting light and preventing hot

air from over-heating the deflector.

Magnetic Deflector

On the reflector plate is mounted the universal magnetic deflector, which is in series

with the lamp and consumes 1 watt. The magnetic deflector can be used with either the 250W

or 400W MA/V lamp. The use of a magnetic deflector enables an MA/V lamp burning horizontally

to be operated with the same efficiency as the normal MA/V lamp.

Weathering Finish

The alloy used is especially selected for its resistance to corrosion. Further protection

is obtained by the use of a special one-coat aluminium finish stove enamel.

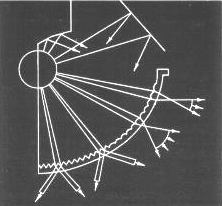

Optical System

The pressed prismatic refractor bowl (Z6630) is made of heat-resisting glass. The refractor

is secured in a die-cast light alloy ring which is supported on the main body casting by

a hinge and quick-release stainless steel toggle catch. The toggle has a safety catch

so that two distinct actions are needed before the refractor swings free. The first action

releases the toggle catch and lowers the hinged ring and refractor to a safety position,

where it is still held at each end. The toggle catch, which is at the bracket end,

can then be unhooked allowing the refractor to swing down, giving access to the lantern

interior. A gasket is fitted in the lower rim of the lantern body and when the

lantern is closed this makes a weatherproof joint with the hinged ring supporting

the bowl.

In use the lamp is mounted with its axis horizontal, and the plane of the rim of

the bowl at about 15° to the horizontal. By arranging for the lampholder to

be outside the bowl and the lamp to enter at an angle (patent applied for)

a compact lantern of small size is possible. The slight upward inclination of

the lantern towards the roadway in use directs maximum amount of light at night on to

the carriageway and adjacent area (verge, footwalk, side turning, etc.) on both sides,

and gives a very pleasing appearance to the lighting units by day. A good light output

ratio (67% - 70%) is obtained and very little light (not more than 8%) is emitted

above the horizontal plane through the light source.

Groups of external shallow vertical fluting on the bowl help to distribute the

bright area over the greater part of the surface of the bowl as seen from normal

directions of view, thereby both adding to the attractive appearance and reducing

any possibility of discomfort glare. Light emitted upwards from the lamp is redirected

downwards by means of an auxiliary reflector system, of high reflectivity, so that,

in conjunction with the refracting elements of the bowl, it is re-disbributed to

suppliment the main distribution of downward light by the bowl.

Groups of external shallow vertical fluting on the bowl help to distribute the

bright area over the greater part of the surface of the bowl as seen from normal

directions of view, thereby both adding to the attractive appearance and reducing

any possibility of discomfort glare. Light emitted upwards from the lamp is redirected

downwards by means of an auxiliary reflector system, of high reflectivity, so that,

in conjunction with the refracting elements of the bowl, it is re-disbributed to

suppliment the main distribution of downward light by the bowl.

The main optical system consists of parallel refracting and diffusing prisms on the inside

of the glass bowl, the outer surfacing being substantially smooth to facilitate cleaning

and to avoid ledges and crevices where dirt can accumulate.

The prinicple of controlled diffusion, originated by the G.E.C. Research Laboratories

for lanterns using the H.P.M.V. lamp, has been adopted, so that in the main beam a

high intensity is obtained from a large area of relatively low brighness. The high

intensities at angles near the horizontal, essential for good road brightness with

normal spacing, are therefore achieved without objectional glare. Each main refracting

flute is designed in accordance with G.E.C. British Patent No. 507688, to contribute to

the peak intensity (at an angle between 79° and 75%deg; to the downward vertical),

and a significant proportion (decreasing with the intensity and with inclination to

the vertical) contribute light at lower angles. Cross-refracting prisms are used

on the lower part of the bowl to redistribute the more steeply downward light,

with intensity increasing at the wider angles up to peak direction.

The shape of the bowl has been specially designed to enable flutes of the nature

described to be used, whilst avoiding any "back" faces which give rise to losses of

light (patent applied for). No element on the inner surface of the bowl has any

face not used to direct light into a required direciton. Usually in a multiple prism

type refractor each prism has a "back" face, forming the step to the main refracting

face of the next prism. Although in a good design the inclination of such a face is

calculated so that the face intercepts as little light as possible, such a "back" face

always involves some wastage of light. By adopting a formation of flutes and prisms

which avoid the need for any "back" face, light losses from this cause are

eliminated.

|

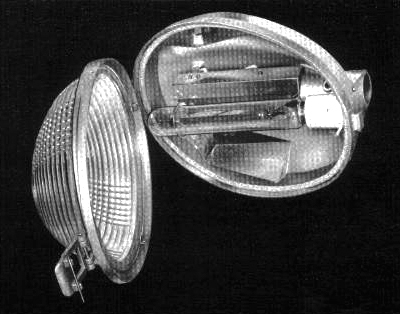

| The lantern with the refractor bowl lowered showing the lamp, reflectors and

general construction. |

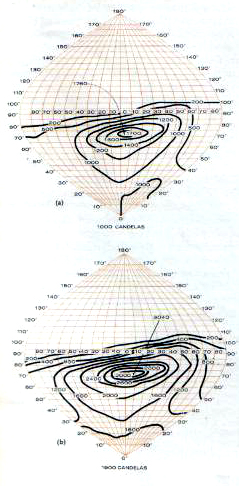

The iso-candela diagrams are based on an average lamp light output through life from:

(a) 250W Osram mercury type MA/V lamp (8,750 lumens average).

(b) 400W Osram mercury type MA/V lamp (16,000 lumens average).

| 250W | 400W |

| Directional intensity ratio | 2.0:1 | 1.9:1 |

| Light above horizontal | 7.5% | 8% |

| Light output ratio | 67% | 70% |

| Lumens in the lower hemisphere | 5,420 | 10,030 |

Light distribution data are given for the guidance of the lighting engineer and represent the

average results of laboratory tests on a number of lanterns taken at random from stock.

The data are based on the lamp characteristics stated; if the latest lamp efficiency is different,

the candela or lumen values should be calculated in direct proportion to the relative lamp

lumens.

Lantern weight: 18lb (8.16 kg).

|