|

Group A Sodium Lantern

Application

The lantern is designed for Group A installations as defined in B.S.C.P. 1004.

For Groups A1 and A2 mounting heights up to 35 ft. can be used and for Group A3

up to 40 ft.

The lantern is of good appearance and has other applications such as the lighting of

car parks and otehr open spaces.

The lantern is designed to use one 150W Osram SOX type sodium lamp.

Mounting

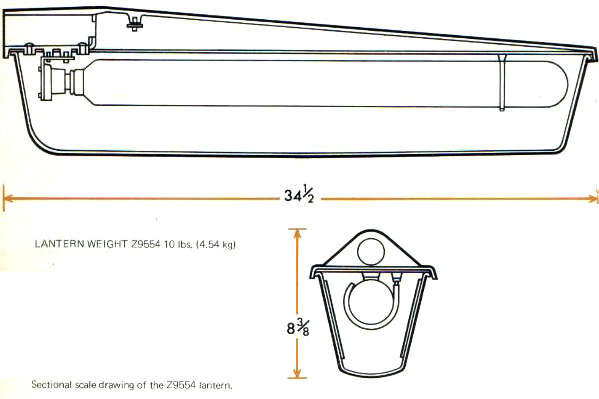

A side entry socket is provided to accept a 5" length of unthreaded 1¼" B.S.P.

A baffle is provided at the end of the socket to prevent the entry of water.

Lantern Construction

The lantern complies with all respects of B.S. 1788 and is Kitemarked. The body is die cast

in LM6 silicon aluminium alloy. All external metal parts for the hinges and fastenings are

made in stainless steel.

A special feature is the removable bowl. When the bowl is hanging in the open position,

it cannot be accidently dislodged, but by turning it through 90° it can be lifted off,

there are no loose parts.

The bowl is formed from Acrylic sheet and has refactor plates cemented on, the prisms are

totally enclosed.

A porcelean B.C. lampholder is fitted. The lampholder is wired to the terminal block with

non-hygroscopic woven glass insultated cable.

Optical System

The distribution of the lantern complies with B.S. 1788 types S.C.O.(S). The main beams

are produced by a combination of a bare lamp and a double refractor plate. The white enamelled

body cating forms a secondary diffusing reflector over the lamp. The bottom of the bowl is

diffused and is part of the optical system. The ends of the bowl are figured with a decorative

pattern.

Finish

The lantern is supplied with good quality synthetic enamel finish stoved on after

pre-treatment and primer have been applied.

Lamp Operating Gear Recommended

Z1718 Transformer, tapped 200/250 volts to BS.3768

Z1780X capacitor, 15 m.f.d

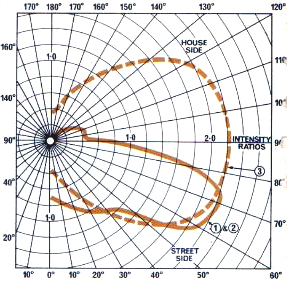

(1) Prinicple vertical polar curve.

(1) Prinicple vertical polar curve.

(2) Polar curve in a vertical plane parallel to street axis.

(3) Principle conical polar curve.

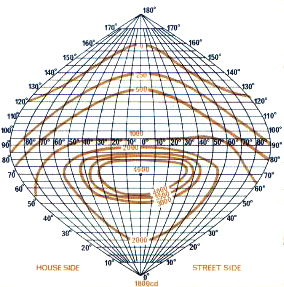

The above iso-candela diagram is based on an average lamp light output through life from

a 150 Watt Osram High Efficiency SOX sodium lamp 19,500 lumens average, applicable at time

of print.

The above iso-candela diagram is based on an average lamp light output through life from

a 150 Watt Osram High Efficiency SOX sodium lamp 19,500 lumens average, applicable at time

of print.

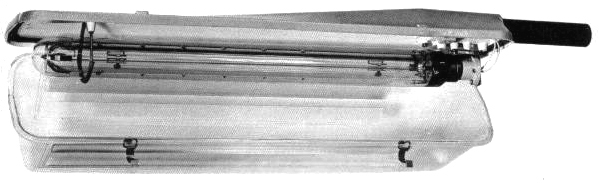

The Z9554 side entry lantern with the bowl opened to show the lamp mounting and general construction.

The Z9554 side entry lantern with the bowl opened to show the lamp mounting and general construction.

| Light flux in lower hemisphere (lumens) |

13,800 |

See CP1004 Tables 10-16 |

| Downward light output ratio |

0.71 |

No limits specified |

| Angle of elevation of upper limit of beam |

76½ |

75° must be within beam |

| Angle of elevation of lower limit of beam |

56½ |

75° must be within beam |

| Peak intensity ratio |

2.23 |

1.8 to 4.0 |

| Maximum intensity ratio in the zone from 0° to 30° |

1.07 |

0.3 to 1.7 |

| Minimum intensity ratio in the zone from 0° to 30° |

0.7 |

0.3 to 1.7 |

| Maximum intensity ratio in the zone from 0° to 30°/Peak Intensity Ratio |

0.48 |

0.7 Maximum |

| Angle at which 1.2 intensity ratio occurs above the peak |

84° |

80° to 86° |

| Intensity ratio at the horizontal |

0.57 |

0.7 Maximum |

| Divergence of the beam centre from the axis of the road in azimuth |

Zero |

15° Maxiumum |

|