|

Stanton

|

Stanton Ironworks Company Limited

Nottingham

England

|

1950s logo

|

Mid 1950s logo

|

Made by the centrifugal process, the firm's columns are available in a variety of styles, colours and finishes.

As columns have been made for the past five years, then the firm commenced manufacturing of concrete columns

in 1933. Their 1938 exhibit included two columns for Group A and Group B lighting. The firm have also completed

their new plant - the most modern in the country - which enables them to supply large quantities of columns

with the utmost dispatch. A new and patented method of erecting 25-foot standards with brackets ensures

that the bracket arm can be securely fixed in any required position. A special bracket for use with

raising or lowering gear, can also be supplied for standards of 25 feet. - APLE Conference Programme 1938

Installation in Coalville in 1939

The success of centrifugal spinning methods in manufacturing concrete pipes let

Stanton experiment somes years ago with a similar process making

reinforced-concrete lamp columns. They have now had six years experience in

manufacturing concrete lamp columns and the method of manufacturing a concrete column

using moulds, reinforcement steel rods, vibration and spinning is described. Such is

the strength of their reinforced columns that independent tests have

shown a comprehensive strength of more than 10,000 lbs. per square inch. - APLE Conference Programme 1939

The firm's lighting standards combine utility and economy with a pleasing

appearance particularly when used on modern roads or housing estates.

A unique finish is the Granolithic finish produced by grinding the surface

after moulding to resemble natural stone. The pleasing shade of grey that

results is achieved without the use of any form of colouring matter. The spinning

mould method by which the Standards are produced results in concrete free from

porosity and gives freedom from maintenance costs. Standards are available in

a wide range of designs suitable for all the usual forms of gas and electric

lighting. - APLE Conference Programme 1945

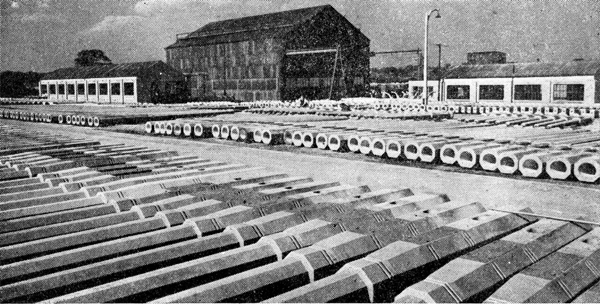

Corner of Stanton stockyard in 1945

Stanton columns in Leicester 1945-46

Stanton Spun Concrete Lighting Standards are made in various designs to suit every locality.

Economical in use, they require no painting or maintenance, because the smooth granolithic finish,

obtained by grinding after moulding, is permanent amd impervious to atmospheric

conditions. Manufactured by the centrifugal spinning method they possess

great strength and density, the steel reinforcement giving added strength to

resist impact shocks. Made to British Standards throughout, they are available

in several colours to suit requirements. Permanency of colouration is

assured by introducing the coloured cement into the mould during the spinning

process, thus ensuring complete penetration of the standard by the colour. - APLE Conference Programme 1946

Columns are available in a wide range of designs to suit any locality and harmony with existing surroundings. Manufactured by the

centrifugal spinning process and conforming to British Standard 1308:1946 they possess great strength and

density. A fabricated reinforcement frame gives added strength to resist impact shocks. The columns are ground mechanically

after spinning to a smooth granolithic finish which is permanent and impervious to atmospheric conditions. Columns are now

supplied with concrete doors which give access to spacious accommodation for all forms of lighting controls and winches where

necessary. Over 400 Municipal undertakings have installed Stanton Columns. Most have sent in repeat orders. - APLE Conference Programme 1947

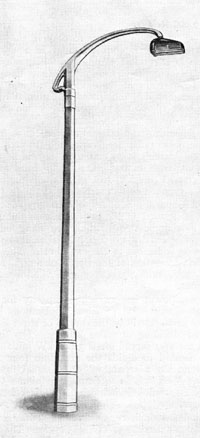

Stanton 6B column with BLEECO Streamline sodium lantern as

displayed at the Princes Park, Southport, during the APLE Conference. - Public Lighting #47, 1947

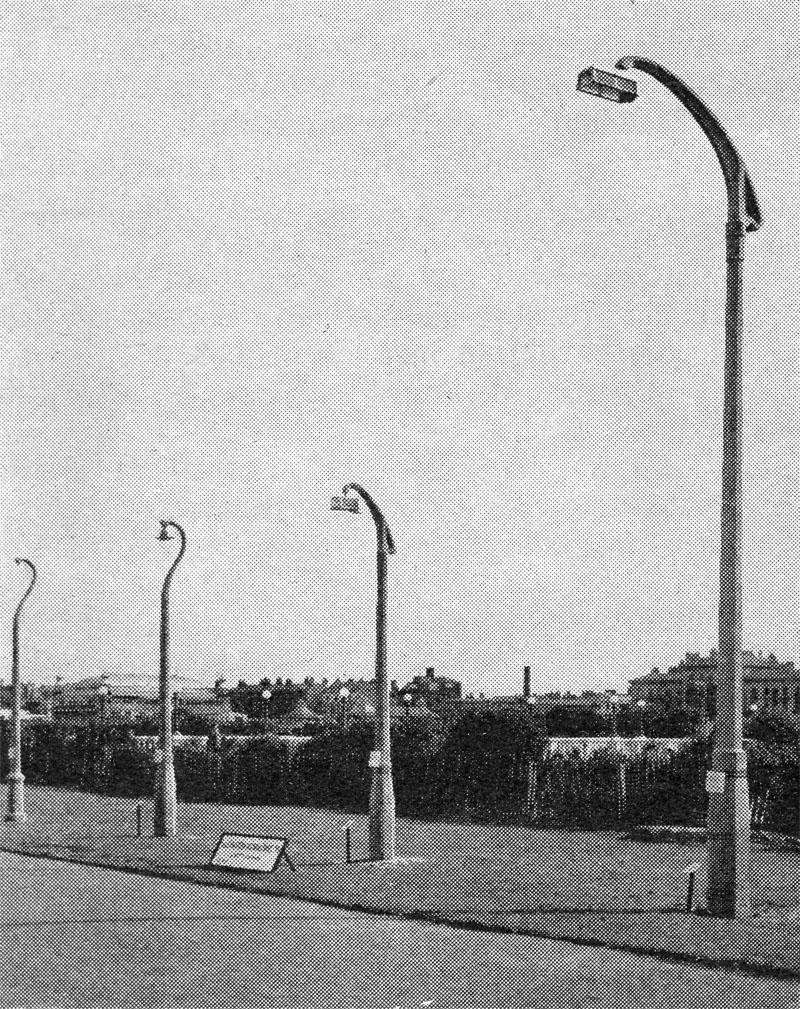

Stanton display at Princes Park, Southport, during the APLE Conference. From left to right: Type 1B,

Type 7A (with Metropolitan Vickers lantern), Type 7B

(with GEC Z9420 sodium lantern - as installed in Salisbury) and Type 6B

(with BLEECO Streamline sodium lantern).- Public Lighting #47, 1947

References:

APLE Conference Programme Bournemouth 1938

APLE Conference Programme Glasgow 1939

APLE Conference Programme Glasgow 1945

APLE Conference Programme London 1946

APLE Conference Programme Southport 1947

- External Links:

- Grace's Guide

|